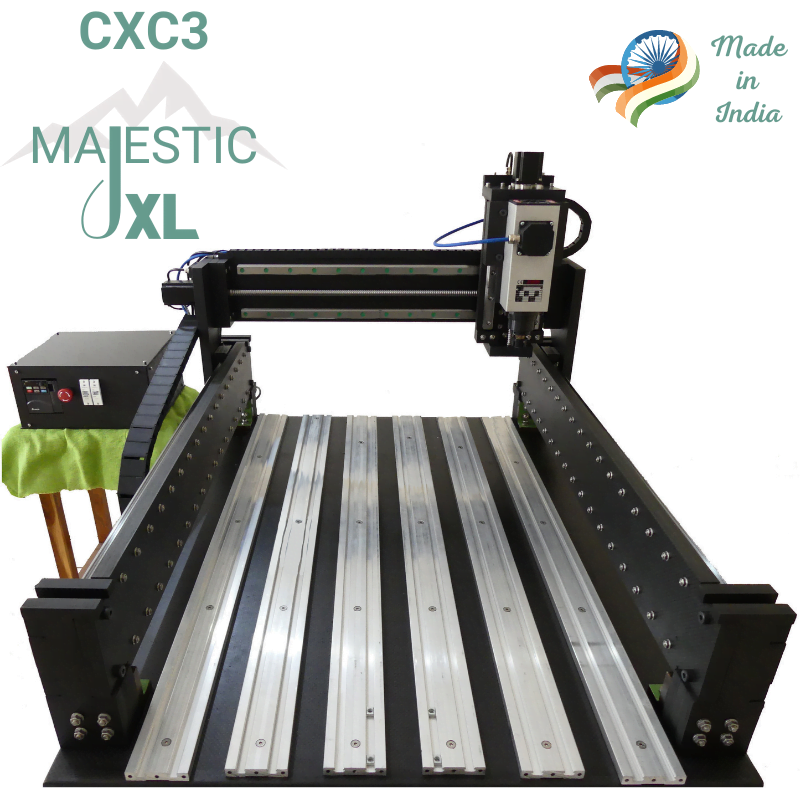

The CXC3 Majestic XL by Akriti Precision Systems, a leading CNC machine manufacturer based in Bangalore, India, stands as a testament to cutting-edge engineering. Known for its robust design and high precision, this 3-axis CNC machine has been crafted with about 75% of its parts manufactured in India, while the remaining components are sourced from trusted international suppliers in Italy, Germany, Japan, Taiwan, Korea, and France. The thoughtful selection of parts plays a critical role in the machine’s longevity and performance. In this article, we’ll explore the various CNC machine parts used in the CXC3 Majestic XL and why their quality is key to building reliable, high-performing machines.

1. Frame and Base Structure

The backbone of any CNC machine is its frame and base, which provide the stability required during machining operations. In the CXC3 Majestic XL, the frame is made from precision-engineered, world’s first Composite Superstructure, designed to dampen vibrations and enhance accuracy. This ensures that the machine maintains structural integrity for a lifetime, allowing for precise cuts and minimal error margins.

2. Linear Motion Guideways

One of the critical CNC machine parts used in the CXC3 Majestic XL is the linear motion guideways. These components are crucial for guiding the movement of the machine’s axes. The CXC3 uses high-quality guideways from Hiwin Taiwan, known for their low friction and high durability. These guideways ensure smooth and precise motion, reducing wear and tear over time, and maintaining the machine’s performance for years.

3. Ball Screws

Ball screws are another vital part of the CNC machine’s axis movement system. In the CXC3 Majestic XL, the ball screws are manufactured with precision in Taiwan. These ball screws help convert rotational motion into linear motion with minimal friction, ensuring precise positioning of the tool head. The high-quality material and design prevent backlash, a common issue in low-end CNC machines, ensuring consistent performance.

4. Spindle and Stepper Motor

The spindle, driven by a high-power motor, is the heart of any CNC machine, as it holds and rotates the cutting tool. The CXC3 Majestic XL features an Italian-made Teknomotor spindle, known for its superior reliability and power. This spindle can reach high speeds without compromising on stability, making it perfect for high-precision jobs. The motor paired with this spindle is a high-performance unit, sourced from Japan, which provides consistent torque and smooth operation, even during demanding machining processes. Servo motors, if opted for, are sourced from USA.

5. Controller and Electronics

The brain of the CXC3 Majestic XL is its controller, which interprets the instructions from the CAD/CAM software and directs the movements of the machine. The machine utilizes a sophisticated control system manufactured in India, known for its robust performance in industrial applications. This advanced control system enables seamless automation and precise control over the machining process, making complex designs easier to execute. The electronics made in India, work in harmony to ensure safety and precision throughout the machine’s operations.

6. Software Interface

While the physical components of the machine are vital, the software interface plays an equally important role. The CXC3 Majestic XL is equipped with user-friendly open-source software that allows for easy programming and operation. This software integrates seamlessly with popular CAD/CAM systems, making it accessible for operators of all skill levels and utilizes GRBL.

The Importance of Quality CNC Machine Parts

The performance of any CNC machine is only as good as the parts used in its construction. The CXC3 Majestic XL demonstrates this with its combination of locally manufactured components and imported parts from some of the best suppliers globally. The CNC machine parts used in this machine, such as precision ball screws, high-performance spindles, and advanced control systems, are all chosen to ensure that the machine can handle the rigors of daily use while maintaining a high level of precision and accuracy.

Using high-quality parts not only improves the machine’s performance but also enhances its lifespan. A machine built with inferior parts may require frequent maintenance or replacement, leading to increased downtime and costs. In contrast, a machine like the CXC3 Majestic XL, built with durable, high-quality components, offers reliable performance over a longer period, making it a smart investment for businesses. Furthermore, the combination of local and imported parts ensures that this machine remains cost-effective while meeting global standards for precision and durability.

Conclusion

In summary, the CNC machine parts used in the CXC3 Majestic XL are selected with meticulous attention to quality and performance. By blending Indian manufacturing with internationally sourced components from Italy, Germany, Japan, Taiwan, Korea, and France, Akriti Precision Systems has created a CNC machine that excels in precision, durability, and efficiency. The thoughtful integration of these high-quality parts ensures that the CXC3 Majestic XL not only meets the demands of today’s industries but will continue to perform reliably for years to come. Investing in a machine like this, built with quality parts, is crucial for businesses seeking long-term productivity and success.