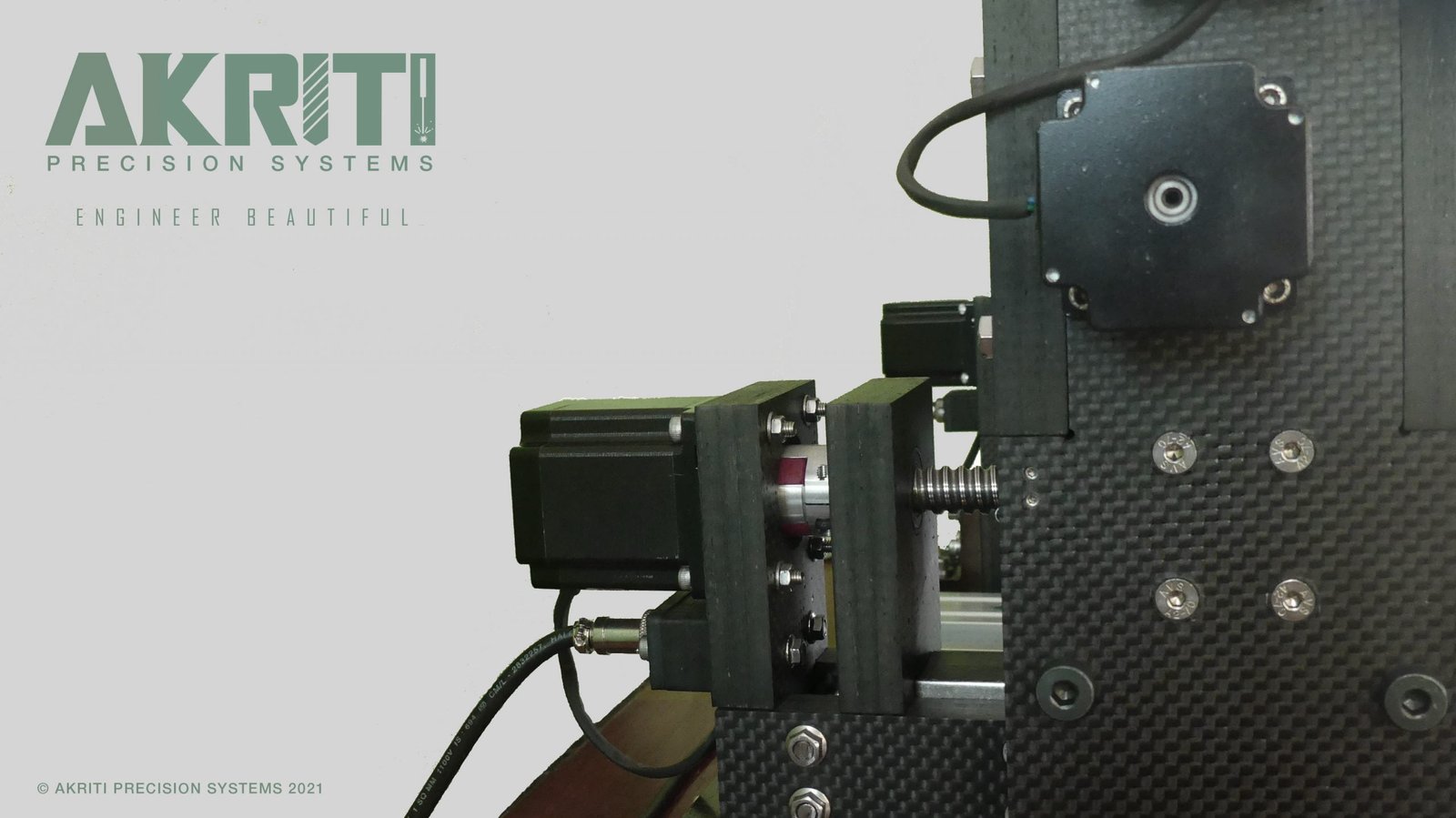

Stepper motors play a crucial role in the high-precision CNC machines developed by Akriti Precision Systems, Bangalore. Known for their reliability and accuracy, these machines incorporate advanced stepper motors to ensure superior performance in various industrial applications. Akriti Precision Systems uses high-quality Made in India Mechtex steppers or Made in Japan Tamagawa steppers in its CNC machines. By integrating these top-tier motors, the company enhances the precision, durability, and efficiency of its machines, which are made with approximately 75% Indian-manufactured parts, while the remaining components come from renowned suppliers in Italy, Germany, Japan, Taiwan, Korea, and France. These CNC machines are proudly designed and manufactured in India with the highest standards in mind, making them a benchmark for quality in the industry.

What Are Stepper Motors?

A stepper motor is an electromechanical device that converts electrical pulses into discrete mechanical movements. Each pulse moves the motor in precise, fixed steps, making it ideal for applications requiring exact positioning. The uses of stepper motor technology in CNC machines allow for unparalleled control over the movement of machine components, which is essential for tasks that demand accuracy and repeatability.

Stepper Motors in CNC Machines: Precision and Control

In CNC machines, stepper motors are used to control the movement of the tool head or worktable. Whether it’s milling, cutting, or engraving, precise motion control is critical to achieving accurate results. The uses of stepper motor technology in these machines provide exact positioning without requiring feedback systems like encoders. This contributes to the machine’s simplicity while maintaining high accuracy.

Akriti Precision Systems utilizes stepper motors from Mechtex and Tamagawa to ensure that its CNC machines can execute complex tasks with the required precision. These motors drive the axis of the machine, ensuring smooth, coordinated movement between different parts.

High-Quality Parts for Superior Performance

The quality of the stepper motors used in Akriti Precision Systems’ CNC machines is pivotal to their performance. The company selects only the best parts from trusted suppliers in countries such as Japan, Italy, and Germany. For stepper motors, they rely on Mechtex, a well-established Indian manufacturer, and Tamagawa, a global leader from Japan. Both companies are known for their high-quality motors, which ensure durability, reliability, and efficient operation.

By using Made in India Mechtex steppers, Akriti Precision Systems supports local manufacturing while maintaining international quality standards. These motors offer high torque, low noise, and long operational life, making them perfect for CNC machines used in industries like automotive, aerospace, and electronics.

Advantages of Stepper Motors in CNC Machines

- Precise Positioning: The stepper motors used in CNC machines offer high accuracy in controlling the position of the cutting or milling tool. Each pulse corresponds to a specific angle of rotation, allowing for controlled movements without the need for a feedback mechanism.

- Repeatability: One of the key uses of stepper motor technology is its ability to repeat the same motion with precision. This makes stepper motors ideal for applications where consistency is critical, such as mass production.

- Low Maintenance: Stepper motors require less maintenance compared to other motor types, such as servo motors. They have fewer components that can wear out, which reduces downtime and maintenance costs.

- High Torque at Low Speeds: Stepper motors generate high torque even at low speeds, which is beneficial for CNC machines performing intricate tasks that require slow and precise movements.

- Cost-Effectiveness: Stepper motors are often more affordable than other types of motors, making them an excellent choice for CNC machines that need to balance performance and cost. Akriti Precision Systems’ use of Indian-manufactured stepper motors helps to further reduce costs while ensuring top-tier performance.

Why Akriti Precision Systems Stands Out

Akriti Precision Systems not only provides CNC machines with superior performance but also promotes the use of high-quality, Made in India components. Their focus on sourcing 75% of the machine parts locally ensures that they contribute to the “Make in India” initiative, supporting local industries and reducing dependency on foreign imports. The remaining parts are sourced from reputed suppliers in Europe and Asia, ensuring that all components meet international standards of excellence.

Moreover, by integrating Mechtex and Tamagawa stepper motors, Akriti Precision Systems delivers machines that are reliable, efficient, and suitable for a wide range of industrial applications. The choice of stepper motors plays a significant role in the overall performance of CNC machines, providing smooth, precise movements essential for producing high-quality components.

Final Thoughts

The uses of stepper motor technology in CNC machines are fundamental to achieving the precision, reliability, and control needed in today’s manufacturing processes. Akriti Precision Systems, with its focus on high-quality parts from both Indian and international suppliers, ensures that its CNC machines meet the highest standards of performance. Whether using Mechtex steppers from India or Tamagawa steppers from Japan, Akriti Precision Systems guarantees that its machines offer unparalleled precision and durability, making them a trusted choice for industries that demand excellence.

By leveraging the latest advancements in stepper motor technology, Akriti Precision Systems continues to lead the way in producing world-class CNC machines that support the “Make in India” initiative while incorporating the best global technologies.