75% PARTS MANUFACTURED IN INDIA

Selected:

Dimensions (Outer) - Length | 1970 MM |

Dimensions (Outer) - Width | 1320 MM |

Dimensions (Outer) - Height | 730 MM |

Dimensions (Build / Cutting Area) | 1520 MM |

Dimensions (Build / Cutting Area) | 900 MM |

Dimensions (Build / Cutting Area) | 150 MM |

Max Stock Height (Z Axis) | 200 MM |

Max Stock Length (4th / A Axis) | 1320 MM |

Electronics Board - Dimensions | 360 (L) x 360 (W) x 190 (H) (MM) |

Chassis | Akriti Composite Superstructure |

Max Travel Speed (X Axis) | 6 Meters / Minute |

Max Travel Speed (Y Axis) | 6 Meters / Minute |

Max Travel Speed (Z Axis) | 6 Meter / Minute |

Spindle - Brand | Teknomotor - Air Cooled |

Spindle - Model | COM41470408 |

Spindle - Bearings | Double Bearing |

Spindle - Power | 2.2 KW / 3 HP |

Spindle - Voltage in Volts | 380 / 220 |

Spindle - MAX FREQ. HZ | 400 Hz |

Spindle - MAX RPM | Max 24,000 RPM |

Spindle - Current in Amps (Star / Delta ) | 5.2 / 9.0 A |

Spindle - Weight | 8.5 KG-s / 18.7 LBS |

Spindle - Collet | ER 20 |

Spindle Maximum Run-out | Less than 20 Microns / 0.02 MM |

Spindle - Materials Capability | Soft Metals - Aluminium, Copper, Brass, Bronze, Zinc, Nickel, All Non Ferrous metals and alloys. |

Drive - X Axis | Hiwin Rolled Ball Screw & Nut - 20 MM |

Drive - Y Axis | Hiwin Rolled Ball Screw & Nut - 20 MM |

Drive - Z Axis | Hiwin Rolled Ball Screw & Nut - 20 MM |

Guides - X Axis | Hiwin 25 MM Linear Guide & Block - 2 Lengths |

Guides - Y Axis | Hiwin 25 MM Linear Guide & Block - 2 Lengths |

Guides - Z Axis | Hiwin 25 MM Linear Guide & Block - 2 Lengths |

Ball Screw Nut Type | Square Nut |

Stepper Motor (X & Y Axis) - Model | NEMA 34, Bipolar - Stepper Motor (Made in Japan) |

Stepper Motor (X & Y Axis) - Motor type | Hybrid Stepper Motor |

Stepper Motor (X & Y Axis) - No. of steps/rotation | 200 |

Stepper Motor (X & Y Axis) - Holding Torque | 350 NCm |

Stepper Motor (Z & A Axis) - Model | NEMA 24, Bipolar - Stepper Motor |

Stepper Motor (Z & A Axis) - Motor type | Hybrid Stepper Motor |

Stepper Motor (Z & A Axis) - No. of steps/rotation | 200 |

Stepper Motor (Z & A Axis) - Holding Torque | 210 NCm |

Repeat Positioning Accuracy | <50 Microns / <0.05 MM |

Single Step Movement by Stepper | 2.5 Microns / 0.0025 MM |

Stepper Motor Drivers - Max Current | 7 AMPS |

Stepper Motor Drivers - Voltage Input | 24 - 48 Volts DC |

Stepper Loop Type | Open Loop |

Spindle Control | VFD - Spindle Control |

Stock / Material Fixturing Support - 3 Axis | Aluminium - M5 T-slot Profiles - Pre-installed |

Stock / Material Fixturing Support - 4th Axis | 100 MM Dia 4 Jaw Chuck |

Stock / Material Fixturing Support - Tailstock | Universal with locking mechanism |

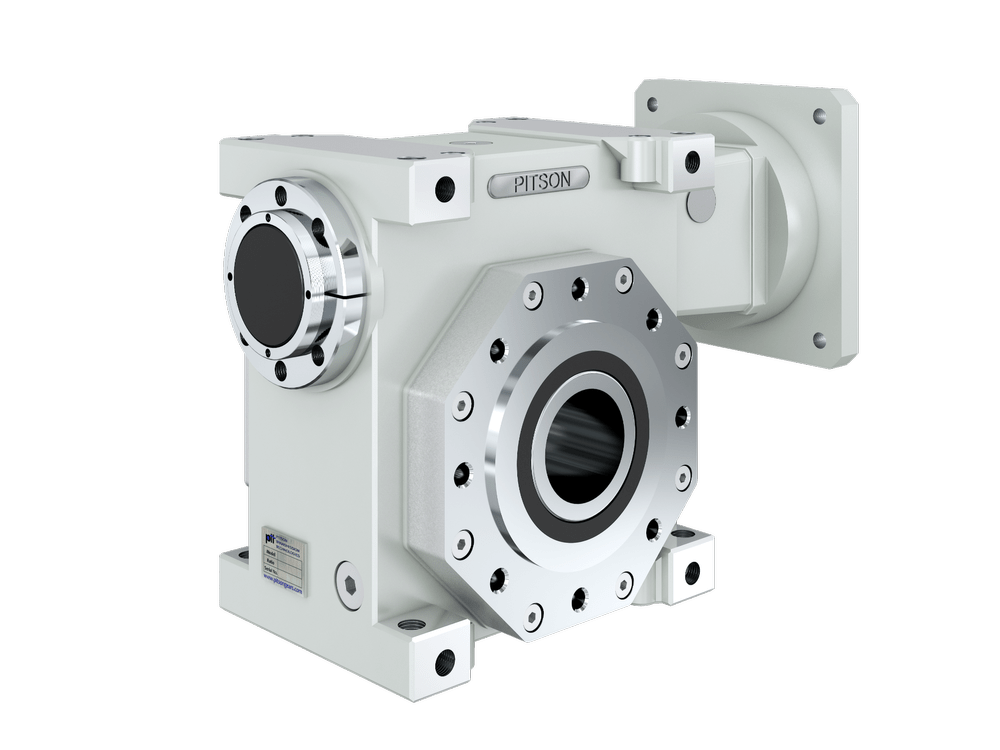

4th Axis - Gearbox Type | Wormgear with Pre-Load |

4th Axis - Gearbox Precision | Less than 5 ArcMin Backlash |

Movement | Simultaneous 4 Axis Motion - Full Interpolation |

Machine Movement Type | Moving Gantry System |

Power Input | Single Phase Input - 220V / 110V |

Current | 16 Amp Plug Point Required |

Power Supply | 36 V 10 Amp - SMPS |

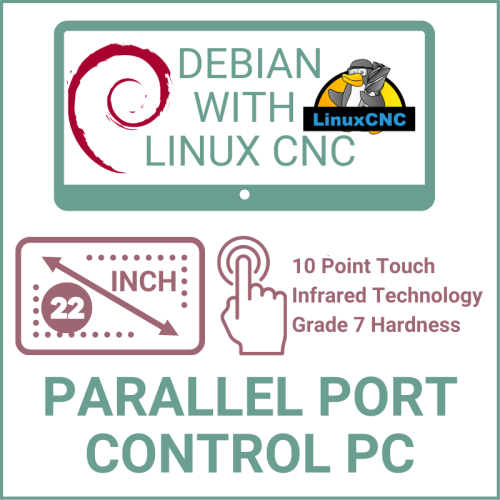

Controller | Parallel Port Based LinuxCNC Desktop PC Controller |

Ship Configuration | Ships Fully Assembled with selected accessories |

Continuous Operations | Certified for 24/7 Operations |

Warranty | 1 Year Warranty - All Parts Covered |

Extended Warranty | Up to 10 Years Extended Warranty - Optional |

Maintenance Contracts | Annual Maintenance Contracts - Optional |

Certification | CE Certified |

CAM Support | Fully compliant with GCODE / MCODE |

OS Support | LinuxCNC - Included & Configured with PC |

Included PC Specifications | 16GB of RAM, AMD 3200G Processor, 256 GB SSD, 22 Inch FullHD Monitor |

Metric / Imperial Support | Supports Both MM & Inches |

Calibrated By | All of our measurements are made with Mitutoyo calibrated instruments |

CNC Machine w/Electronics Box

Milling Bits - 5 PCS,

---3MM Dia Single Flute Bit (for Aluminum / Acrylic / ACP)

---4MM Dia Straight Bit

---6MM Dia Straight Bit

---3MM Dia Corn Bit

---3MM Dia V Point Carving Bit

ER 16/20/25 Collet (Based on Spindle) - 3 PCS

---3MM Dia

---4MM Dia

---6MM Dia

T Nuts (For Securing the Material) - 10 Pcs

Spanner Compatible with Spindle Nut with Rubber Grip - 1 Piece

Long Controller Connector Cable - 1 Piece

Stock Mounting Bolts & Nuts - 8 Pcs

Composite Stock Holders - 4 Pcs

The device features a Dual Lead Worm design, where the left and right flanks of the worn shaft utilize different lead angles, allowing for gradual changes in tooth thickness and enabling precise backlash adjustment.

Additionally, an input shaft with coupling helps prevent backlash at the input, further enhancing the accuracy of the system. The Made in India 4-axis Wormgear is a reliable and versatile solution for applications requiring precise indexing and motion control.

Parallel Port Controller, which is made in India and features the LinuxCNC operating system.

This controller & PC is embedded in the electronics box of the CNC and is an optional upgrade for a touchscreen interface at an additional cost.

Alternatively we can provide a non-touchscreen option as well.

We offer two additional CNC controller options (Upgrades) that can be configured with our CNC machines to enhance their functionality.

Experience the precision and versatility of the Made in India 4 Axes CNC Controller – TNC-M24. This controller is designed for optimal performance, featuring G-code programmability and step and direction outputs for stepper drivers.

The X, Y, and Z axes provide smooth linear motion, while the fourth axis adds rotational capability as A, B, or C axis, delivering unparalleled flexibility to your system.

The second option is the Ethernet Controller, manufactured in Hungary. This controller does not include a PC and is designed to work with any Windows computer (not included).

It provides seamless connectivity and compatibility with a wide range of Windows systems. You can use their own UCCNC Control software or Mach 3/4.

It can be configured with a Touch / Non-Touch PC & monitor combination.

Regarding warranty offerings, we provide comprehensive coverage to ensure your peace of mind. With our OSL Coverage

One Year

Full Warranty, you can enjoy a worry-free first year of ownership, knowing that any manufacturing defects or issues will be promptly addressed.

Six Years

Extended Warranty (optional), allowing you to extend the coverage up to a total of 6 years 1 or 3 years, tailored to your needs.

Lifetime

Lifetime Warranty for the superstructure. This ensures the longevity of your investment and provides enduring protection and assurance. Read more about why we offer this warranty below..

Our products are made from Carbon Fibre & Fibre Glass, Composite Sandwich Structure – Ranging from 5 MM to 25 MM as needed. It provides the following benefits as compared to standard Steel or Aluminium framed CNC’s

We prepared and got a 6 MM thick piece of composite tested by Underwriters Laboratory. You can access their reports by clicking on theirl logog below.

Teknomotor CNC Spindle – MODEL – COM41470329

KW – 2.2

V (Δ/Y) – 220/380

MAX FREQ. HZ – 400

MAX RPM – 24,000

CURRENT (Δ/Y) – 9.0 / 5.2

KG’S – 8.48

COLLET – ER 25

BEARINGS – Double Ceramic Bearings

Please visit akriti.tech for all the products, accessories and services offerred.