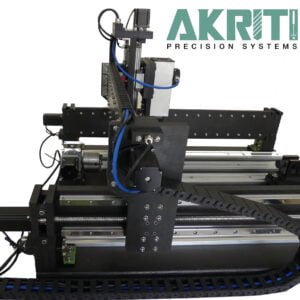

CXC3 PCB PrecisionProXL CNC – 3 Axis CNC Machine

Build Area – 600 MM / 500 MM / 100 MM |

Call / Whatsapp / Telegram – +91 9019054837 |

Email – contact@akriti.tech |

CXC3 PCB PrecisionProXL – A 3 Axis CNC Machine for PCB Engraving, Etching & Drilling

Description

World's Best Desktop / Tabletop CNC Machines

CXC3 PCB PrecisionProXL CNC

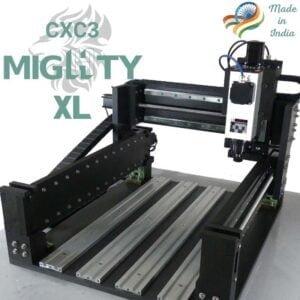

Introducing the CXC3 PCB PrecisionProXL CNC from Akriti Precision Systems, a state-of-the-art 3 Axis CNC machine. This versatile machine is designed specifically for Engraving, Etching, Milling & Drilling on Gold, Silver, Copper & Brass, offering a build area of 600 MM / 500 MM / 100 MM.

The CXC3 PCB PrecisionProXL stands out with its 80% parts manufactured in India and the remaining sourced from countries like Italy, Germany, Japan, China, France, Taiwan, and Italy. It boasts of <50 Micron Repeat positioning.

This machine comes with a 1-year warranty on the full product and a lifetime warranty on the Composite Superstructure. The warranty can be extended up to 10 more years.

The CXC3 PCB PrecisionProXL is equipped with a Arduino Uno R3 controller, offering affordability, ease of use, and customization. Additional controller options are available for upgrade.

Experience one of the world’s best desktop/tabletop CNC machines for PCB Routing & Drilling with the CXC3 PCB PrecisionProXL. Contact Akriti Precision Systems at +91 9019054837 or email at contact@akriti.tech for more information.

80% PARTS MANUFACTURED IN INDIA

20% PARTS ITALY, GERMANY, JAPAN, China, TAIWAN & ITALY

Minimal

Maintenance

<50 Micron Repeat positioning

Open Source

SW & HW

Online & Remote

Support Options

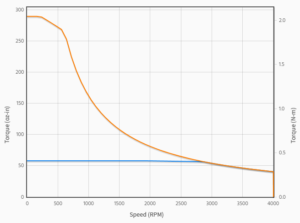

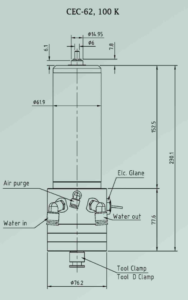

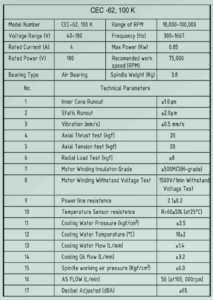

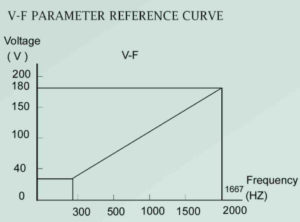

Spindle - CEC HF 62 - 60K

Technical Specifications

Dimensions (Outer) - Length | 1000 MM / 100 CM / 40 In / 3.3 Ft |

Dimensions (Outer) - Width | 700 MM / 70 CM / 28 In / 2.3 Ft |

Dimensions (Outer) - Height | 500 MM / 50 CM / 20 In / 1.7 Ft |

Dimensions (Build / Cutting Area) | 500 MM / 50 CM / 20 In / 1.7 Ft. |

Dimensions (Build / Cutting Area) | 600 MM / 60 CM / 24 In / 2 Ft. |

Dimensions (Build / Cutting Area) | 100 MM / 10 CM / 04 In / 0.3 Ft. |

Max Stock Height (Z Axis) | 170 MM / 17 CM / 07 In / 0.6 Ft. |

Electronics Board - Dimensions | 360 (L) x 360 (W) x 190 (H) (MM) |

Chassis | Akriti Composite Superstructure |

Max Travel Speed (X Axis) | 4 Meters / Minute |

Max Travel Speed (Y Axis) | 4 Meters / Minute |

Max Travel Speed (Z Axis) | 4 Meters / Minute |

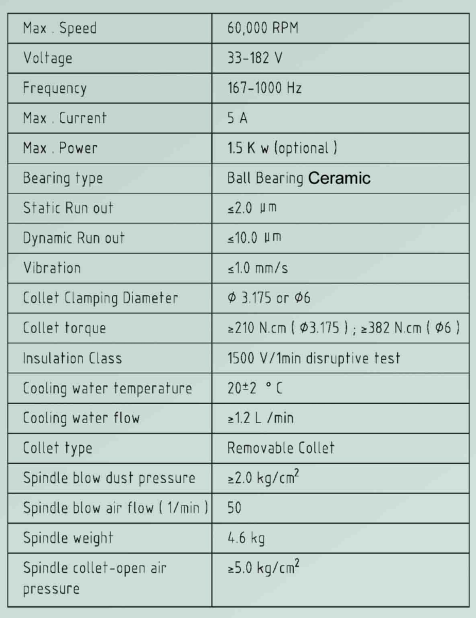

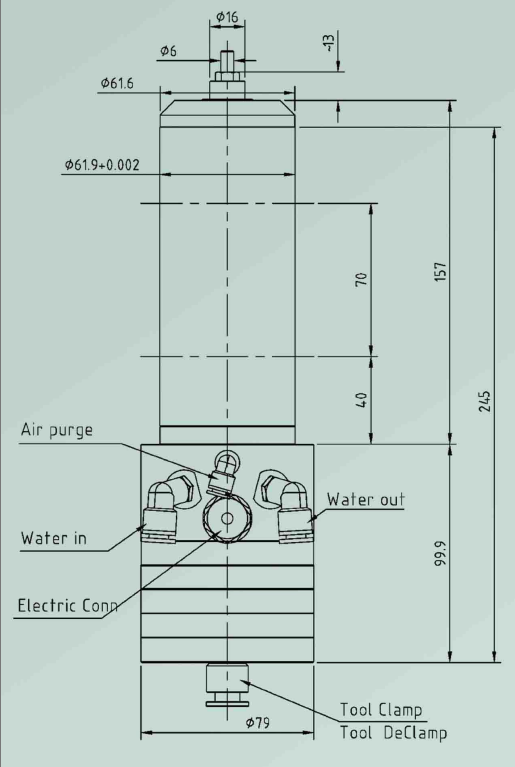

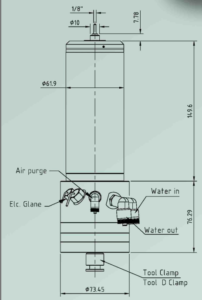

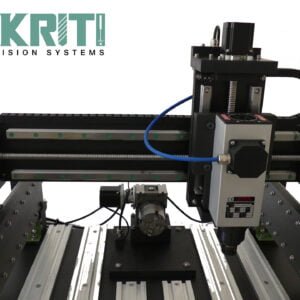

Spindle - Brand | Capital Spindles - Water Cooled |

Spindle - Model | CEC HF 62 - 60K |

Spindle - Bearings | Double Bearing - Ceramic |

Spindle - Power | 1.5 KW / 2 HP |

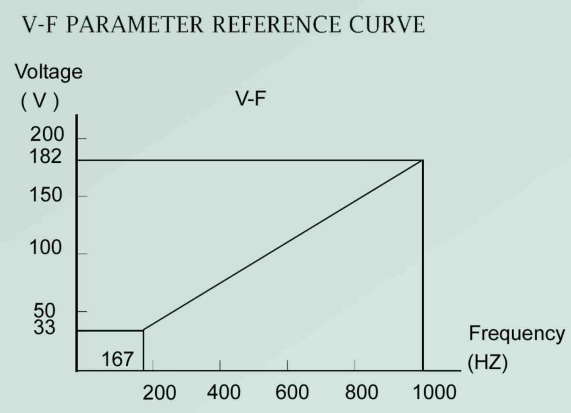

Spindle - Voltage in Volts | 33 - 182 |

Spindle - MAX FREQ. HZ | 1000 Hz |

Spindle - MAX RPM | MAX 60000 RPM |

Spindle - Current in Amps (Star / Delta ) | 2.1 / 3.6 A |

Spindle - Weight | 4.6 KGs / 10 LBS |

Spindle - Collet | 6MM DIA - Auto Tool Clamping |

Spindle Maximum Run-out | Less Than 2 Microns / 0.002 MM |

Spindle - Materials Capability | Soft Materials - Wood, MDF, Plywood, Acrylic, Plastics, PEEK, Delrin, Rubber, Silicon, Composites, Foam, PCB, Styrofoam |

Drive - X Axis | Hiwin Rolled Ball Screw & Nut - 16 MM |

Drive - Y Axis | Hiwin Rolled Ball Screw & Nut - 16 MM |

Drive - Z Axis | Hiwin Rolled Ball Screw & Nut - 16 MM |

Guides - X Axis | Hiwin/GLT 20 MM Linear Guide & Block |

Guides - Y Axis | Hiwin/GLT 20 MM Linear Guide & Block |

Guides - Z Axis | Hiwin/GLT 20 MM Linear Guide & Block |

Ball Screw Nut Type | Square Nut Implementation |

Stepper Motor (X & Y Axis) - Model | NEMA 24 & 34, Bipolar - Stepper Motor (Made in Japan) |

Stepper Motor (X & Y Axis) - Motor type | Hybrid Stepper Motor |

Stepper Motor (X & Y Axis) - No. of steps/rotation | 200 |

Stepper Motor (X & Y Axis) - Holding Torque | 78 kgf·cm |

Stepper Motor (Z Axis) - Model | NEMA 23, Bipolar - Stepper Motor |

Stepper Motor (Z Axis) - Motor type | Hybrid Stepper Motor |

Stepper Motor (Z Axis) - No. of steps/rotation | 200 |

Stepper Motor (Z Axis) - Holding Torque | 110 NCm |

Repeat Positioning Accuracy | <50 Microns / <0.05 MM |

Single Step Movement by Stepper | 2.5 Microns / 0.0025 MM |

Stepper Motor Drivers - Max Current | 4 AMPS |

Stepper Motor Drivers - Voltage Input | 24 - 48 Volts DC |

Stepper Loop Type | Open Loop |

Spindle Control | VFD - Spindle Control |

Stock / Material Fixturing Support | Aluminium - M5 T-slot Profiles - Pre-installed |

Movement | Simultaneous 3 Axis Motion - Full Interpolation |

Machine Movement Type | Fixed Gantry System |

Power Input | Single Phase Input - 220V / 110V |

Current | 16 Amp Plug Point Required |

Power Supply | 36 V 10 Amp - SMPS |

Controller | Arduino - USB |

Ship Configuration | Ships Fully Assembled with selected accessories |

Continuous Operations | Certified for 24/7 Operations |

Warranty | 1 Year Warranty - All Parts Covered |

Extended Warranty | Up to 10 Years Extended Warranty - Optional |

Maintenance Contracts | Annual Maintenance Contracts - Optional |

Certification | CE Certified |

CAM Support | Fully compliant with GCODE / MCODE (GRBL) |

OS Support | Windows XP (64 bit), 7, 8, 10, 11, MacOS X, Linux (any), Raspberry Pi / ARM |

Minimum Control PC Specification | 2GB of RAM and a 1280 x 768 screen size |

Recommended Control PC Specification | 8GB of RAM, Intel 8th Gen Processor / AMD Zen 3 Architecture Processor & a minimum 1280 x 768 screen size |

Included PC Specifications | - 22 Inch Full HD Monitor |

Metric / Imperial Support | Supports Both MM & Inches |

Calibrated By | All of our measurements are made with Mitutoyo calibrated instruments |

Laser - Type | Not Included - Optional |

Includes the Following | - Fully Covered Enclosure & Machine Base - Dust Shoe for Vacuum Dust Evacuation - Vacuum not included -PC with Monitor (Machine Control & CAM Software) |

What's provided with the Machine?

-

Machine

CNC Machine w/Electronics Box & PC with Monitor

-

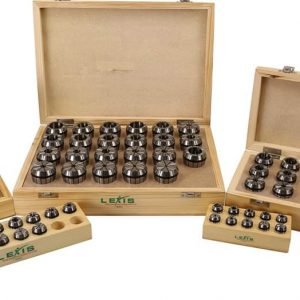

Cutting Bits

Milling Bits - 4 PCS, For PCB Routing, Drilling, Clearing & Contouring

-

Others

T Nuts (For Securing the Material) - 10 Pcs

Long Controller Connector Cable - 1 Piece

Stock Mounting Bolts & Nuts - 8 Pcs

Composite Stock Holders - 4 Pcs

The Controller

CNC Controller - TNC-M24

Using an Arduino Uno R3 as a controller for CNC machines offers several benefits. First, it provides an affordable and accessible option for hobbyists and small businesses to build their own CNC machines.

The Arduino Uno R3 is widely available and relatively inexpensive, making it an attractive option for those on a budget. Second, the Arduino Uno R3 is easy to use and program, even for those without extensive programming experience.

Its open-source nature means that there are many resources available online, including tutorials and code libraries, to help users get started. Finally, the Arduino Uno R3 offers flexibility and customization options, allowing users to tailor their CNC machines to their specific needs and preferences.

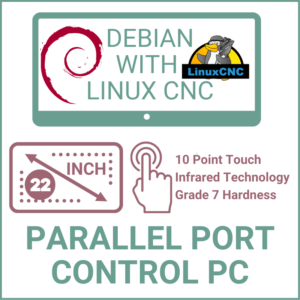

We offer two additional CNC controller options (Upgrades) that can be configured with our CNC machines to enhance their functionality.

The first option is the Parallel Port Controller, which is made in India and features the LinuxCNC operating system.

This controller & PC is embedded in the electronics box of the CNC and is an optional upgrade for a touchscreen interface at an additional cost.

Alternatively we can provide a non-touchscreen option as well.

The second option is the Ethernet Controller, manufactured in Hungary. This controller does not include a PC and is designed to work with any Windows computer (not included).

It provides seamless connectivity and compatibility with a wide range of Windows systems. You can use their own UCCNC Control software or Mach 3/4.

It can be configured with a Touch / Non-Touch PC & monitor combination

Product Warranty

Regarding warranty offerings, we provide comprehensive coverage to ensure your peace of mind. With our OSL Coverage

One Year

Full Warranty, you can enjoy a worry-free first year of ownership, knowing that any manufacturing defects or issues will be promptly addressed.

Ten Years

Extended Warranty (optional), allowing you to extend the coverage up to a total of 10 years 1 or 3 years, tailored to your needs.

Lifetime

Lifetime Warranty for the superstructure. This ensures the longevity of your investment and provides enduring protection and assurance. Read more about why we offer this warranty below..

composite superstructure - lifetime warranty

Our products are made from Carbon Fibre & Fibre Glass, Composite Sandwich Structure – Ranging from 5 MM to 25 MM as needed. It provides the following benefits as compared to standard Steel or Aluminium framed CNC’s

- Metal Fatigue – Doesnt suffer form sagging, hoggingor metal fatigue over time.

- Vibration Dampening Properties – Composites have a high loss co-efficient and the structure is able to reduce / absorb vibrations leading to reduced chatter when milling / cutting materials

- Light & Strong – Composites are less dense than steel and are yet comparable to them in Strength & Stiffness

We prepared and got a 6 MM thick piece of composite tested by Underwriters Laboratory. You can access their reports by clicking on theirl logog below.

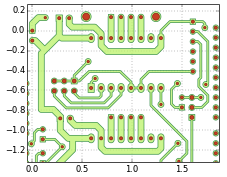

PCB Design & Machining Softwares - Gerber / Drill Files

Beginner – Free / Open Source

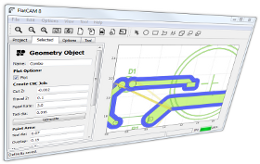

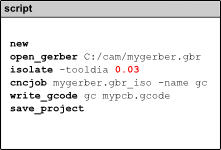

FlatCAM lets you take your designs to a CNC router. You can open Gerber, Excellon or G-code, edit it or create from scatch, and output G-Code. Isolation routing is one of many tasks that FlatCAM is perfect for. It’s is open source, written in Python and runs smoothly on most platforms. Check out the features list.

Some features…

Viewer

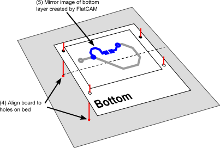

Double-Sided

Make double-sided PCBs quickly with a specialized built-in tool that allows you to invert your layers and create alignment guides.

Power Features

A TCL console provides the ultimate flexibility for users to automate and implement their own features.

Website – http://flatcam.org/

Advanced – Free / Open Source

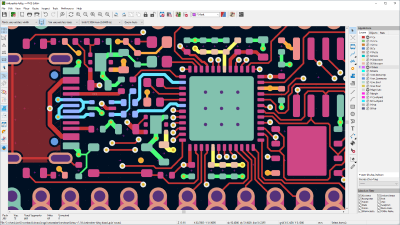

KiCad EDA

A Cross Platform and Open Source Electronics Design Automation Suite

Some features…

Schematic Capture

KiCad’s Schematic Editor supports everything from the most basic schematic to a complex hierarchical design with hundreds of sheets. Create your own custom symbols or use some of the thousands found in the official KiCad library. Verify your design with integrated SPICE simulator and electrical rules checker.

PCB Layout

KiCad’s PCB Editor is approachable enough to make your first PCB design easy, and powerful enough for complex modern designs. A powerful interactive router and improved visualization and selection tools make layout tasks easier than ever.

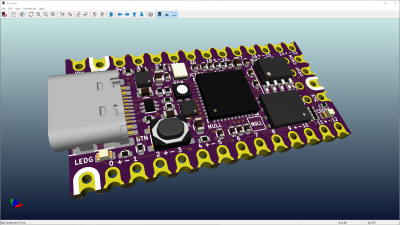

3D Viewer

KiCad’s 3D Viewer allows easy inspection of your PCB to check mechanical fit and to preview your finished product. A built-in raytracer with customizable lighting can create realistic images to show off your work.

Gerber Viewer

View your gerbers before sending out to manufacturing or just general review of third party gerbers.

SPICE Simulation

KiCad integrates the open source spice simulator ngspice to provide simulation capability in graphical form through integration with the Schematic Editor.

Compatible with various spice models

The use of ngspice grants compatibility with existing models meant for:

Advanced – Paid & Proprietary

Beginner / Advanced – Paid & Proprietary

Website – https://www.altium.com

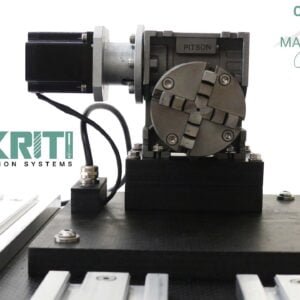

Options, Upgrades & Accessories

Servo Motors

Laser Options

Convert your CNC into a 2-in-1 Machine. Laser Modules can be attached with a magnetic jig to the spindle. Perform basic engraving and cutting tasks of various materials.

Controllers

Coolant & Clamping Systems

Other CNC Accessories/Options

Warranty Options

Spindle Upgrade

CNC Spindle – MODEL – CEC HF 62 – 100K

KW – 0.85

V (Δ/Y) – 180

MAX FREQ. HZ – 300-1667

MAX RPM – 100,000

CURRENT (Δ/Y) – 4 A

KG’S – 3.8

COLLET – 6MM DIA – Auto Tool Clamping

BEARINGS – Hybrid Bearings

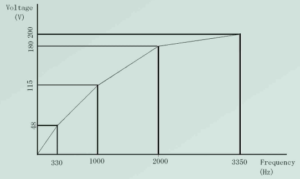

CNC Spindle – MODEL – CEC HF 62 – 200K

KW – 0.85

V (Δ/Y) – 38-200

MAX FREQ. HZ – 334-3350

MAX RPM – 200,000

CURRENT (Δ/Y) – 3 A

KG’S – 3.9

COLLET – 6MM DIA – Auto Tool Clamping

BEARINGS – Hybrid Bearings

Akriti Videos

Request a Quote For this Machine

Subscribe to our Newsletter

Additional information

| Weight | 100 kg |

|---|---|

| Dimensions | 600 × 400 × 150 mm |