Ever wondered how that perfectly detailed toy car came to be, or how that sleek phone case achieved such a smooth finish? The answer might surprise you: it’s all thanks to a marvel of modern manufacturing called CNC machining. But what exactly is CNC machining, and how does a cnc machine work?

Unpacking the Power of CNC

CNC stands for Computer Numerical Control, and essentially, a CNC machine is a computer-controlled device that can precisely move a tool or a workpiece. Imagine a robot workshop on steroids, capable of drilling, milling, cutting, and engraving with incredible accuracy and speed. That’s the magic of CNC machining!

Step-by-Step: How a CNC Machine Brings Your Vision to Life

So, how does this wonder machine translate a computer program into a tangible object? Let’s break down the process:

Software

- Design Takes Center Stage: The journey begins with your design. Using Computer-Aided Design (CAD) software, you create a digital blueprint of your project. This blueprint is then converted into a special code called G-code or M-code, which acts as a set of instructions for the CNC machine.

- Feeding the Machine with Instructions: Once the code is ready, it’s uploaded into the CNC machine’s control unit. This can be done through various methods like a keyboard, a USB drive, or even a network connection.

Hardware

- The Brain Behind the Brawn: The control unit acts as the brain of the operation. It interprets the G-code instructions and sends out signals to two key systems: the driving system and the feedback system.

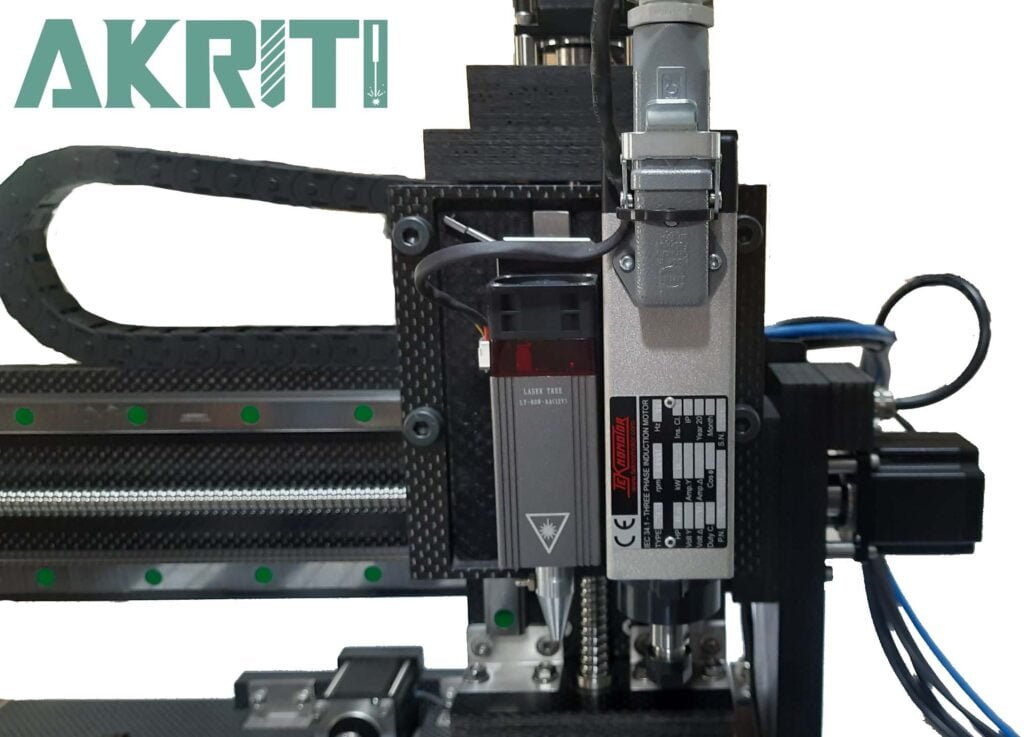

- Driving Towards Precision: The driving system is the muscle of the machine. Comprised of motors, servos, and ball screws, it takes the control unit’s signals and translates them into movement. This movement can be along various axes (X, Y, Z), allowing the machine to position the tool or workpiece with pinpoint accuracy.

- Constant Double-Checking: The feedback system plays a crucial role in ensuring everything runs smoothly. Think of it as a quality control inspector. It constantly monitors the position and speed of the tool or workpiece, sending real-time data back to the control unit. This feedback loop ensures the machine maintains the required precision throughout the process.

- The Magic Touch: Finally, we come to the tool itself. Depending on the desired operation, the CNC machine can be equipped with various tools like drill bits, milling cutters, plasma torches, or even laser beams. Guided by the precise movements of the driving system, the tool performs the designated operation on the workpiece, bringing your design to life.

The Beauty of Versatility: Different CNC Machines for Different Needs

While the core workings of a CNC machine follow these general principles, it’s important to note that there are different types of CNC machines designed for specific applications. Each type may have unique features and functionalities to cater to diverse manufacturing needs.

Ready to Unleash the Power of CNC Machining?

If you’re looking for a reliable and high-precision manufacturing partner, look no further than Akriti Precision Systems CNC! We offer a wide range of CNC machining services and expertise to turn your vision into reality. Contact Akriti Precision Systems today and discover the power of CNC machining for your next project!

How does a cnc machine work?