Ever wondered how those intricate 3D printed figurines or sleek smartphone casings come to life? The answer lies in CNC machines, marvels of engineering that translate digital designs into physical objects. But with 3, 4, and even 5-axis options available, choosing the right CNC machine can feel overwhelming. Fear not, fellow maker! Let’s embark on a journey to understand the key differences between a 3/4/5 Axis CNC machine and empower you to select the perfect tool for your project.

The Power of Axes: How They Shape Your Machining Potential

Imagine a sculptor with a limited set of tools versus one with a vast array. The number of axes on a CNC machine functions similarly. Here’s a breakdown of 3, 4, and 5-axis machines and the incredible possibilities they unlock:

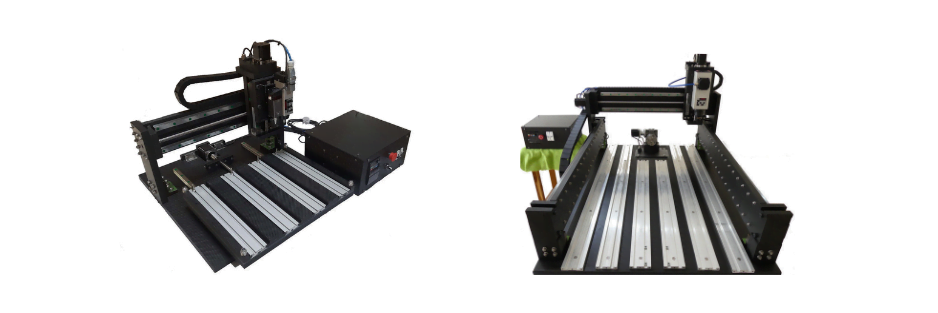

- 3-Axis CNC Machines: These workhorses move along three axes: X (left to right), Y (front to back), and Z (up and down). Think of them as efficient for creating flat surfaces. They’re perfect for projects like signs, plaques, or furniture [link to examples of 3D printed furniture]. Their simplicity and affordability make them a great starting point for beginners. Example – https://www.youtube.com/watch?v=bYxVG-32zZM

- 4-Axis CNC Machines: Take your machining game to the next level with a 4-axis machine! It adds an A-axis, allowing for rotation around the X-axis. Imagine carving intricate details on a sculpture – that’s the power of this additional axis. These machines excel at creating complex shapes, contours, and molds [link to examples of 4-axis machined products]. They offer more flexibility and precision compared to 3-axis machines, making them ideal for projects demanding intricate details. Example – https://www.youtube.com/watch?v=whkWisrxNlU

- 5-Axis CNC Machines: Buckle up for the ultimate machining experience! A 5-axis machine boasts five axes of movement – X, Y, Z, A (rotation around Y), and B (rotation around Z) or C (rotation around Z). Imagine a machine capable of maneuvering a tool at almost any angle – that’s the magic of 5-axis machining. These sophisticated machines are used for producing highly complex parts with tight tolerances and smooth surfaces, like artificial bones, aerospace components, or even cutting-edge military products [link to examples of 5-axis machined products]. Their versatility and productivity make them ideal for high-precision, complex projects. Example – https://www.youtube.com/watch?v=OSdLYLtgnkU

Choosing Your Perfect CNC Match

As you can see, the number of axes significantly impacts a CNC machine’s capabilities, cost, and applications. The key lies in understanding your project needs and budget. Do you require simple, flat cuts? A 3-axis machine might be ideal. Are you craving intricate details and complex shapes? A 4-axis machine could be your best friend. But for those pushing the boundaries of precision and complexity, a 5-axis machine is the ultimate partner.

Ready to unlock the power of CNC machining?

Let Akriti Precision Systems (https://akriti.tech) guide you on your journey. We offer a wide range of CNC machines with varying axes to fit your specific needs. Contact us today and discover how CNC machining can transform your project ideas into reality!