When it comes to brass machining, the precision and quality of CNC machines are paramount. Akriti Precision Systems Private Limited, based in Bangalore, has emerged as a leader in the field, particularly with its Majestic and Mega Series of CNC machines for brass machining. These machines offer unparalleled performance for both 3 and 4 Axis operations, catering to a wide range of requirements, from small workshops to large-scale manufacturing units. This article delves into the key features, benefits, and applications of these affordable yet high-quality CNC machines designed specifically for brass machining.

Understanding CNC Machines

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by allowing for high-precision machining of metals, including brass. Unlike manual machining, CNC machines are programmed to perform precise cuts, shapes, and drilling tasks automatically, ensuring uniformity and reducing the margin for error. For brass machining, which requires meticulous handling due to the material’s properties, CNC machines provide an ideal solution.

Benefits of Using CNC Machines for Brass Machining

Brass, known for its strength, conductivity, and aesthetic appeal, is a popular material in various industries, such as electronics, automotive, and plumbing. CNC machines, particularly those equipped with 3 and 4 Axis capabilities, offer significant advantages:

- Precision and Accuracy: CNC machines ensure that every piece is machined to exact specifications, minimizing waste and ensuring high-quality output.

- Consistency: Whether for prototypes or mass production, CNC machines provide consistent results.

- Efficiency: Automated operations reduce machining time and increase productivity.

Key Features of CNC Machines for Brass Machining

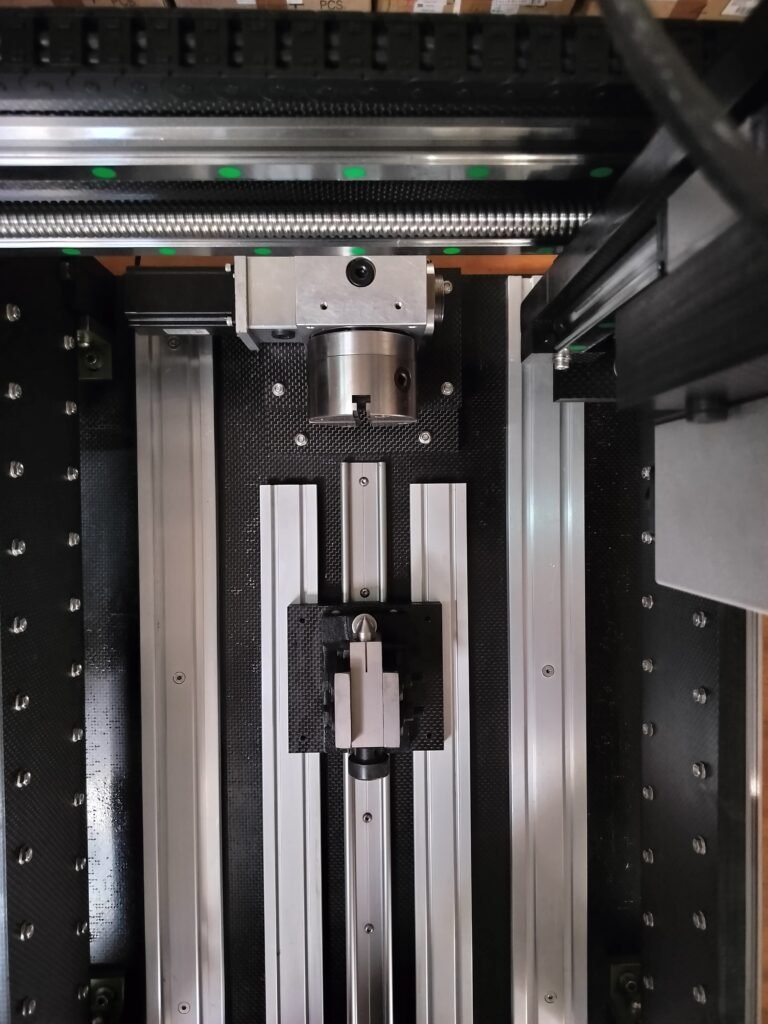

Choosing CNC machines for brass machining requires consideration of certain features. Among the most critical are the machine’s axis operations, build quality, and available working area. The Majestic and Mega Series from Akriti Precision Systems are specifically engineered to meet these demands.

Importance of 3 & 4 Axis Operations

The addition of 3 and 4 Axis operations enhances the versatility of CNC machines. While 3 Axis machines can handle simple tasks like drilling, milling, and cutting, 4 Axis machines introduce an additional rotary movement along the X-axis, enabling more complex shapes and contours to be machined efficiently. This flexibility is particularly beneficial for intricate brass components, allowing for greater precision and reduced handling time.

Majestic Series of CNC Machines by Akriti Precision Systems

The Majestic Series represents a significant advancement in CNC machining technology. These machines are designed to handle a wide range of brass machining tasks with high efficiency and precision.

Technical Specifications and Capabilities

The Majestic Series offers full 3 & 4 Axis operations, with a variety of working areas ranging from 600×400 MM to 1500×900 MM. This range allows manufacturers to choose the best fit for their specific needs. The machines are equipped with high-torque motors, robust spindles, and state-of-the-art controllers, ensuring seamless operations even during high-load conditions.

Applications for the Majestic Series in Brass Machining

- Automotive Components: Perfect for machining brass parts like gears, connectors, and fittings.

- Electronics: Ideal for crafting precision brass connectors and components used in electrical circuits.

- Custom Parts and Prototypes: Useful in creating custom brass parts and prototypes with intricate designs.

- Aerospace Components: Ideal for crafting high-precision brass parts used in aerospace engineering.

- Plumbing and Hardware: Perfect for mass production of brass fittings, valves, and fixtures.

- Jewelry and Decorative Items: Suitable for producing intricate designs and complex shapes in brass.

3 & 4 Axis Operations: A Game Changer in CNC Machining

Understanding the importance of 3 and 4 Axis operations is crucial when choosing a CNC machine. While 3 Axis CNC machines provide adequate precision for most standard tasks, 4 Axis machines introduce rotational capabilities that can significantly expand the range of machining possibilities. This added functionality is invaluable for brass machining, allowing for more intricate cuts and reducing the need for multiple setups.

Working Area Options from 600×400 MM to 1500×900 MM

The variety of working area options provided by Akriti Precision Systems ensures that there is a machine for every type of workshop or production facility. Whether you are looking for a compact 600×400 MM machine for smaller components or a 1500×900 MM machine for larger parts, Akriti’s CNC machines cater to diverse needs.

How to Choose the Right Working Area for Your Requirements

- Small Workshops: Opt for a 600×400 MM or 900×600 MM machine.

- Medium-Sized Production Facilities: A 900×600 MM machine offers a good balance of size and capability.

- Large-Scale Manufacturing Units: For extensive projects, the 1500×900 MM machine is ideal.

Cost-Effectiveness and Quality Assurance by Akriti Precision Systems

Akriti Precision Systems is committed to providing machines that are both affordable and of the highest quality. The company’s focus on precision, durability, and customer satisfaction ensures that every machine is a sound investment. Their CNC machines are competitively priced, making them accessible to businesses of all sizes.

Customer Support and After-Sales Services

One of the key strengths of Akriti Precision Systems is its robust customer support and after-sales services. From installation and training to maintenance and spare parts supply, customers can expect comprehensive support throughout the lifecycle of their machines. Many users have praised Akriti’s responsive service team and their commitment to ensuring maximum uptime for all machines.

Industries Benefiting from Akriti Precision Systems’ CNC Machines

- Automotive: Machining of brass connectors, gears, and fittings.

- Aerospace: Production of high-precision brass components.

- Electronics: Fabrication of brass connectors and intricate parts.

- Plumbing and Hardware: Large-scale production of brass fittings and fixtures.

How to Purchase Majestic and Mega Series CNC Machines

Purchasing a CNC machine from Akriti Precision Systems is straightforward. Interested buyers can use the contact us page or call +919019054837 to discuss requirements and receive tailored recommendations. The company also provides demonstrations and trials for potential buyers.

Frequently Asked Questions (FAQs)

- What is the difference between 3 and 4 Axis CNC machines?

3 Axis machines work along the X, Y, and Z axes, while 4 Axis machines add a rotational axis for more complex machining. - Are Akriti’s CNC machines suitable for small workshops?

Yes, with working areas starting from 600×400 MM, there are options for small to medium-sized workshops. - What materials can be machined with the Majestic and Mega Series?

While they are ideal for brass, these machines can also handle a range of other materials, including aluminum, bronze, copper, gold silver & other non-ferrous materials. - How long is the warranty period for these CNC machines?

Akriti Precision Systems offers a standard one-year warranty with options for extended coverage. - Do these machines come with software?

Yes, both the Majestic and Mega Series come with state-of-the-art CNC software for programming and operation. - Can I get a customized machine?

Akriti Precision Systems offers customization options to meet specific customer needs. Contact us now or call +919019054837 to discuss your customization requirements.

Conclusion

For businesses looking to invest in affordable quality CNC machines for brass machining, the Majestic and Mega Series by Akriti Precision Systems Private Limited offer unparalleled options. With their range of working areas, support for 3 & 4 Axis operations, and a focus on quality and cost-effectiveness, these machines are an excellent choice for both small-scale workshops and large manufacturing units. Explore the advantages of these series and see how they can elevate your brass machining operations to the next level.