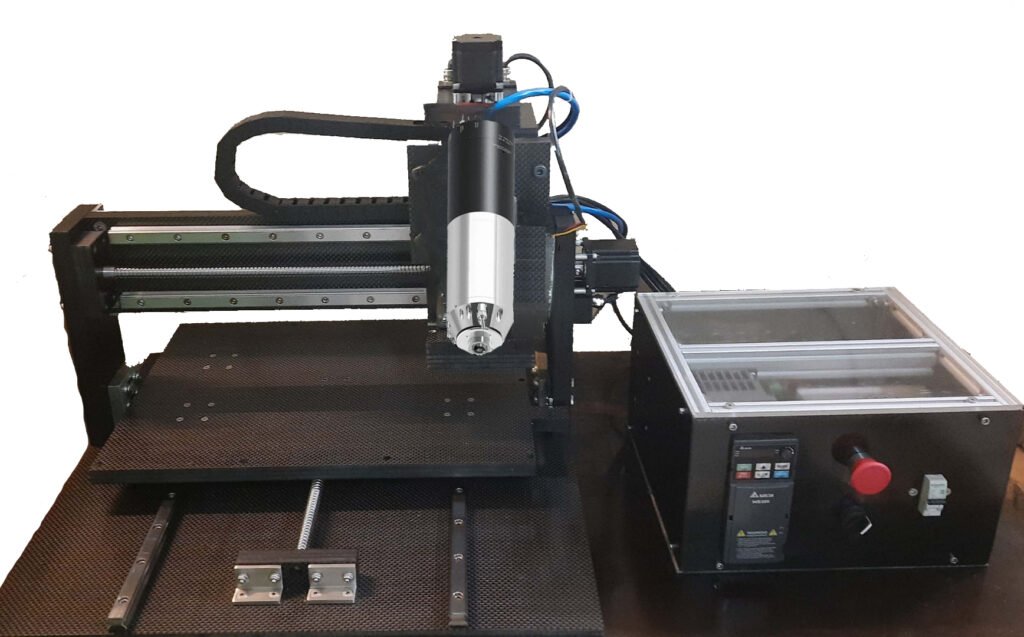

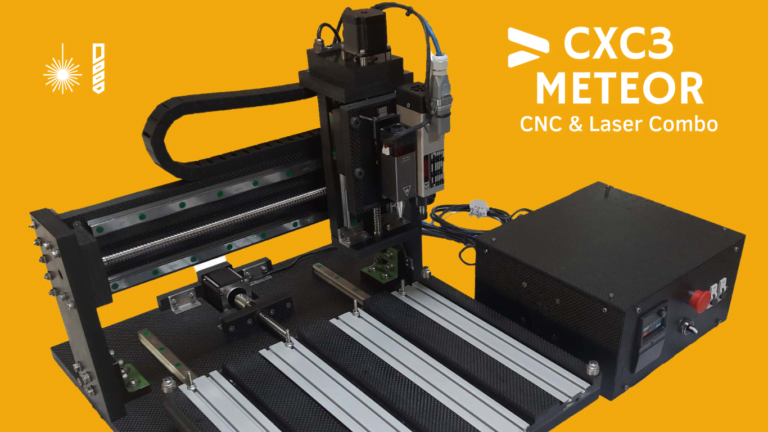

Computer Numerical Control (CNC) machines have revolutionized industries across the globe, and their applications in electrical engineering are no exception. Whether in research and development (R&D) or full-scale manufacturing, the uses of CNC machines span across various electrical engineering tasks. Both 3-axis and 4-axis CNC machines offer precise control over materials, allowing for intricate designs, prototyping, and mass production. In this context, Akriti Precision Systems, a leading Indian CNC machine manufacturer based in Bangalore, stands out for its advanced machines, which are made with approximately 75% of parts manufactured in India. The remaining parts are sourced from top suppliers in Italy, Germany, Japan, Taiwan, Korea, and France, ensuring global standards of quality.

1. Role of CNC Machines in Electrical Engineering R&D

In electrical engineering research and development, precision is key. Developing complex circuits, custom enclosures, and electrical components requires accurate prototyping. 3-axis and 4-axis CNC machines provide the necessary precision and flexibility to achieve this.

Prototyping Circuit Boards

One of the most significant uses of CNC machines in electrical engineering R&D is the rapid prototyping of printed circuit boards (PCBs). A CNC machine can carve out intricate paths on the board material, minimizing human error and allowing for quick design iteration. This process is faster and more cost-effective than traditional methods.

Custom Component Fabrication

Researchers often require custom electrical components for unique experiments. CNC machines, especially 4-axis models, can easily machine intricate geometries that traditional methods struggle to replicate. With Akriti Precision Systems, an Indian CNC machine manufacturer, these machines are optimized for high-precision tasks, making them ideal for R&D labs looking to create complex prototypes.

2. Electrical Enclosures and Mounting Structures

Electrical engineering applications frequently involve custom enclosures for housing sensitive electronics. These enclosures need to be precisely cut to fit specific dimensions while maintaining structural integrity. Akriti Precision Systems offers 3 and 4-axis CNC machines capable of delivering these highly accurate cuts. These machines not only shape the outer shell of the enclosure but can also drill exact mounting holes for components, ensuring seamless assembly.

3. Milling and Drilling for Electrical Connectors

Milling and drilling are common operations in the creation of electrical connectors. These connectors require intricate geometries for both functionality and reliability. CNC machines excel in this area, particularly 4-axis CNC machines, which offer rotational capabilities. This allows the machine to cut complex paths without manual repositioning of the workpiece, increasing efficiency and accuracy.

For instance, connectors that need specialized threading or complex geometries benefit significantly from Akriti Precision Systems’ machines. This Indian CNC machine manufacturer ensures that their equipment can meet stringent requirements, essential in electrical engineering applications.

4. CNC Machining for Sensor Manufacturing

The growing importance of sensors in electrical systems has created a demand for highly precise manufacturing methods. CNC machines, with their ability to carve out intricate parts from a range of materials, are ideal for producing sensor components. 3-axis CNC machines handle planar parts, while 4-axis models can manage more complex, three-dimensional components.

In this field, CNC machines are crucial for creating sensor housings, enclosures, and mounting hardware. Akriti Precision Systems provides machines that deliver this high level of precision, ensuring that sensor manufacturing meets the required standards for electrical systems in various industries.

5. Transformer Manufacturing and Custom Coils

Transformers, essential for managing voltage in electrical systems, require highly precise coils and core components. CNC machines are indispensable in creating custom copper or aluminum windings. They provide consistent, repeatable precision, which is essential for the reliability and performance of transformers.

In this domain, Akriti Precision Systems, a trusted Indian CNC machine manufacturer, offers 3-axis and 4-axis machines designed to meet the demands of transformer production. Their CNC machines ensure that the coils are accurately wound and positioned, improving the efficiency of the final product.

6. Use of CNC Machines in PCB Drilling and Routing

Printed circuit boards (PCBs) require accurate drilling for vias, which connect different layers of the board. CNC machines, particularly 3-axis models, are perfect for these operations, as they can achieve the high level of precision necessary for modern multi-layered PCBs. Moreover, CNC routing is used to cut PCBs into their final shapes, ensuring clean edges and precise dimensions.

With Akriti Precision Systems‘ machines, this task becomes more streamlined. Their advanced CNC machines are well-suited for these operations, making them a top choice for PCB manufacturers in India and beyond.

7. Automated Coil Winding for Electrical Motors

In electrical engineering, especially in motor manufacturing, custom coil winding is a critical task. This process, which requires the placement of wire around a core to create electromagnetic fields, can be automated using 4-axis CNC machines. The fourth axis allows for rotational control, which is essential when winding coils in a precise and repeatable manner.

Manufacturers rely on these machines for their ability to produce high-quality, consistent windings. Akriti Precision Systems offers solutions tailored to this need, with CNC machines capable of delivering both speed and accuracy in coil winding applications.

8. Die-Cutting for Electrical Components

The manufacture of various electrical components often involves die-cutting, where materials such as plastics, ceramics, and metals are cut into specific shapes. CNC machines are frequently used for this purpose because of their versatility and accuracy. Whether for insulating components, gaskets, or other electrical parts, CNC die-cutting ensures precision.

The 3 and 4-axis machines from Akriti Precision Systems, an Indian CNC machine manufacturer, handle die-cutting tasks with efficiency and precision, ensuring consistent production quality in the electrical components industry.

9. Manufacturing Electrical Terminals and Connectors

Electrical terminals and connectors are vital for ensuring the safe transfer of electrical signals and power. CNC machines can manufacture these parts with tight tolerances, ensuring reliable performance. The versatility of CNC machining allows for the creation of both standard and custom designs, making it ideal for electrical terminals that must meet stringent industry standards.

For manufacturers, Akriti Precision Systems provides reliable CNC machines that ensure these components are crafted with high precision, supporting industries that require durable and efficient electrical connectors.

10. Surface Finishing of Electrical Parts

In electrical engineering, the surface finish of components can be just as critical as their dimensional accuracy. CNC machines are used not only for cutting and shaping but also for finishing surfaces to improve conductivity, insulation, or even heat dissipation. These capabilities are especially important in applications where parts will be exposed to harsh environments or require precise electrical properties.

With Akriti Precision Systems, manufacturers get machines capable of performing these complex finishing operations, enhancing both the functionality and durability of electrical components.

Conclusion

The uses of CNC machines in electrical engineering are vast and varied, from prototyping to full-scale production. Whether it’s creating custom circuit boards, electrical enclosures, or transformers, CNC machines ensure precision and repeatability. Akriti Precision Systems, a leading Indian CNC machine manufacturer, delivers 3-axis and 4-axis machines designed for the exacting demands of the electrical engineering sector. Their machines, built with high-quality parts sourced both domestically and from trusted global suppliers, offer a robust solution for manufacturers and researchers alike.

For companies looking to innovate in the field of electrical engineering, CNC machines are indispensable tools that enable high precision, flexibility, and efficiency in both R&D and manufacturing.