Stepper motors play a central role in modern automation, robotics, and precise positioning systems. If you’ve ever wondered what is stepper motor and how it works, this article offers a comprehensive guide for beginners. Here, we’ll dive into the details of stepper motors, explore their applications in CNC machines, and introduce some exceptional CNC solutions crafted by Akriti Precision Systems, a premier Indian CNC machine manufacturer based in Bangalore, India.

Akriti Precision Systems has designed high-quality CNC machines for professional and industrial use. With 75% of their machine components manufactured domestically, Akriti is an example of a highly capable Indian CNC machine manufacturer. These CNC machines are built using either Indian or Japanese Tamagawa stepper motors and source additional parts from trusted companies in Italy, Germany, Japan, Taiwan, Korea, and France.

So, let’s begin by understanding what is stepper motor and then explore how they are used in CNC machining and their advantages for precision applications.

1. What is a Stepper Motor?

A stepper motor is a type of electric motor designed to move in small, precise steps. Unlike traditional motors that spin continuously, stepper motors rotate in discrete steps, enabling highly accurate control over the motor’s position. This functionality makes stepper motors ideal for applications requiring precision, such as robotics, 3D printers, and, notably, CNC machines.

2. How Stepper Motors Work

Stepper motors operate based on electromagnetic coils that activate in sequence. When electricity flows through these coils, it creates magnetic fields that turn the rotor in small, controlled steps. Each step represents a fraction of a full rotation, which can range from 1.8 degrees per step for high-precision motors to larger angles for simpler applications.

3. Types of Stepper Motors

- Permanent Magnet Stepper Motors: Use a permanent magnet rotor and are suitable for applications needing moderate precision.

- Variable Reluctance Stepper Motors: Feature a toothed rotor and offer a basic level of control.

- Hybrid Stepper Motors: Combine elements of both permanent magnet and variable reluctance motors, delivering high accuracy and torque, perfect for CNC machines.

4. Advantages of Stepper Motors in CNC Applications

Stepper motors offer several benefits that make them invaluable in CNC machines:

- Precise Positioning: Each step can be precisely controlled.

- No Feedback System Needed: They don’t need additional sensors to determine position, reducing complexity.

- Repeatable Motion: Stepper motors are ideal for tasks requiring repeatable, consistent movements.

- Cost-Effective: Stepper motors provide a balance between precision and cost, making them accessible for CNC machine applications.

5. Applications of Stepper Motors in CNC Machines

Stepper motors are the powerhouses of CNC machines. These machines rely on stepper motors to achieve the precise control needed for cutting, engraving, milling, and drilling operations. By controlling each movement with accuracy, CNC machines ensure excellent quality and repeatability in industrial and manufacturing tasks.

6. Akriti Precision Systems: An Indian CNC Machine Manufacturer

Akriti Precision Systems is a respected Indian CNC machine manufacturer known for quality and innovation. Located in Bangalore, Akriti designs and manufactures CNC machines that utilize either Indian or Japanese Tamagawa stepper motors, ensuring reliability and high performance. With a commitment to quality, about 75% of their machine parts are made in India, while the rest are sourced from Germany, Japan, Italy, Taiwan, Korea, and France.

All of Akriti’s 3-axis CNC models can be transformed into versatile 2-in-1 machines, which come with a complete Lightburn license, enabling users to expand their capabilities with advanced software.

7. Stepper Motors from Tamagawa and Indian Manufacturers

Tamagawa, a Japanese company known for its high-quality stepper motors, provides some of the motors used in Akriti’s CNC machines. The rest are sourced from top Indian stepper motor manufacturers. Both options deliver the reliability and precision that make them suitable for CNC applications, further enhancing the quality of Akriti’s machines.

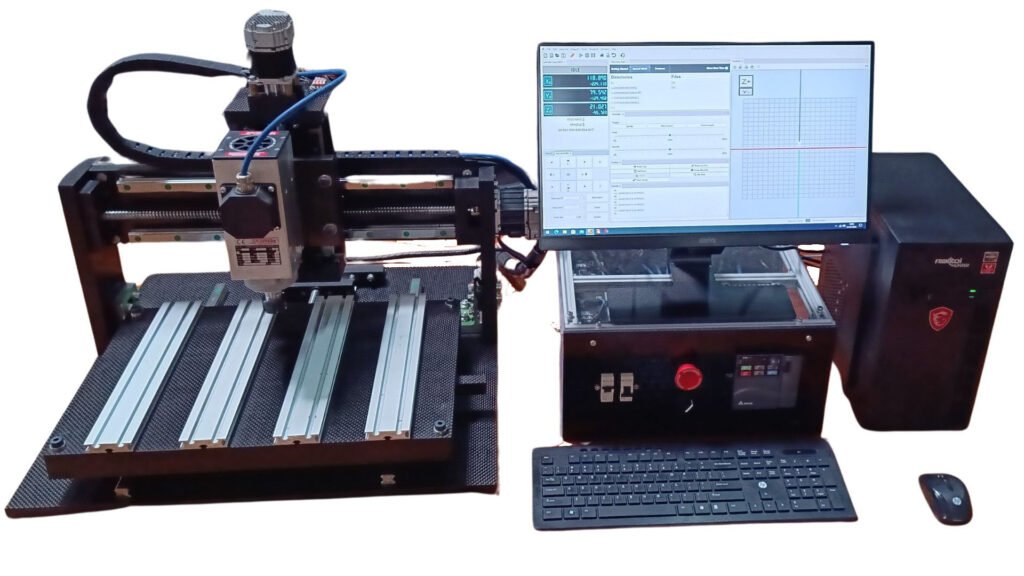

8. PC-Based CNC Controller Software: Universal GCode Sender and Linux CNC

For users of Akriti’s CNC machines, both Universal GCode Sender and Linux CNC are recommended software options. These PC-based controller programs allow users to operate their CNC machines with precision:

- Universal GCode Sender: An open-source software that translates commands into machine-readable instructions, enabling intuitive control over your CNC machine. It’s especially favored by hobbyists and professionals for its simplicity.

- Linux CNC: Designed for Linux-based systems, this controller offers robust, professional-grade capabilities. Linux CNC is highly configurable and suitable for more complex CNC tasks, giving advanced users fine-tuned control over their machine operations.

Both Universal GCode Sender and Linux CNC are ideal for Akriti Precision Systems’ CNC machines, helping users operate their machines seamlessly and with high precision.

9. Why Choose Akriti Precision Systems’ CNC Machines?

Choosing an Indian CNC machine manufacturer like Akriti Precision Systems offers unique benefits, including:

- Superior Local Manufacturing: With 75% of components made in India, Akriti contributes to India’s manufacturing strength.

- International Quality Standards: The remaining parts are sourced from trusted, quality-focused suppliers worldwide, including Germany, Italy, Japan, and Taiwan.

- Upgradeable to 2-in-1 Machines: All 3-axis models can convert into 2-in-1 machines with Lightburn, a high-grade laser software.

These features make Akriti Precision Systems a leading choice for those in need of versatile, high-quality CNC machinery.

10. Stepper Motors: A Future-Ready Solution for Precision Engineering

The use of stepper motors in CNC applications continues to grow, thanks to their reliability and precision. Akriti Precision Systems, an Indian CNC machine manufacturer, exemplifies how stepper motors can be integrated into high-quality CNC machines. With Tamagawa and Indian stepper motors, advanced controller options like Universal GCode Sender and Linux CNC, and a focus on quality, Akriti’s machines are engineered to meet a variety of industrial needs.

11. Conclusion

Now you understand what is stepper motor, how it operates, and why it’s ideal for CNC applications. Whether you’re a beginner or a seasoned professional, stepper motors offer the precision and control needed for accurate positioning. For users seeking CNC solutions in India, Akriti Precision Systems in Bangalore is a top-tier Indian CNC machine manufacturer. By combining locally produced components with international quality parts, Akriti delivers CNC machines that set a high standard for durability, versatility, and performance.

With a commitment to quality and innovative designs, Akriti Precision Systems is poised to continue leading in the CNC machine industry. They bring precision engineering to the forefront with each machine, proving that Indian-made CNC solutions can match global standards.