Dimensions (Outer) - Length | 3000 MM / 300 CM / 118 In / 9.8 Ft |

Dimensions (Outer) - Width | 1800 MM / 180 CM / 71 In / 5.9 Ft |

Dimensions (Outer) - Height | 1050 MM / 105 CM / 42 In / 3.5 Ft. |

Dimensions (Build / Cutting Area) | 2500 MM / 250 CM / 96 In / 8.3 Ft |

Dimensions (Build / Cutting Area) | 1300 MM / 130 CM / 51 In / 4.3 Ft. |

Dimensions (Build / Cutting Area) | 200 MM / 20 CM / 08 In / 0.7 Ft. |

Max Stock Height (Z Axis) | 220 MM / 22 CM / 09 In / 0.72 Ft. |

Electronics Board - Dimensions | 360 (L) x 360 (W) x 190 (H) (MM) |

| Akriti Composite Superstructure & Tata Structura Bed |

Max Travel Speed (X Axis) | |

Max Travel Speed (Y Axis) | |

Max Travel Speed (Z Axis) | |

| |

| |

| |

| |

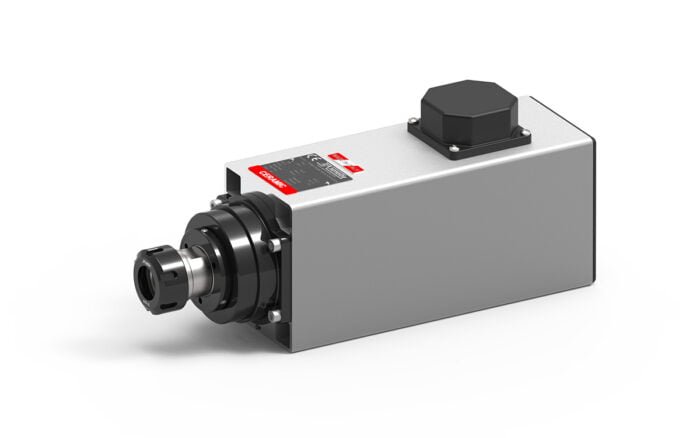

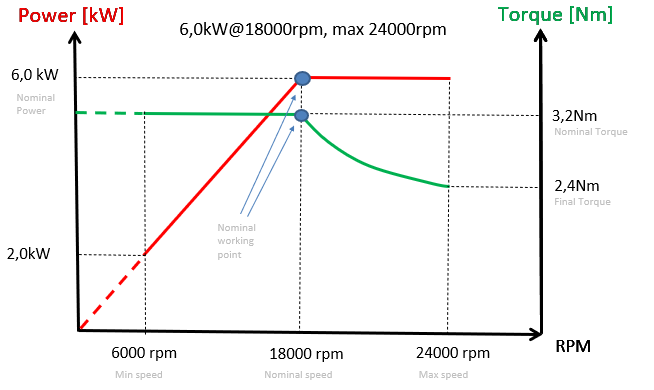

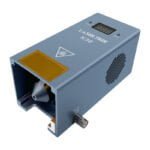

Spindle - Voltage in Volts | |

| |

| |

Spindle - Current in Amps (Star / Delta ) | |

| |

| |

| Less than 20 Microns / 0.02 MM |

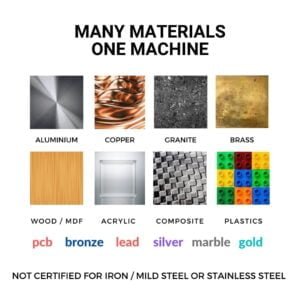

Spindle - Materials Capability | Soft Metals - Aluminium, Copper, Brass, Bronze, Zinc, Nickel, All Non Ferrous metals and alloys.

Soft Materials - Wood, MDF, Plywood, Acrylic, Plastics, PEEK, Delrin, Rubber, Silicon, Composites, Foam, PCB, Styrofoam |

| Rack & Pinion - 1:10 Gearbox |

| Rack & Pinion - 1:10 Gearbox |

| Hiwin Rolled Ball Screw & Nut - 20 MM |

| Hiwin 25 MM Linear Guide & Block - 2 Lengths |

| Hiwin 25 MM Linear Guide & Block - 2 Lengths |

| Hiwin 25 MM Linear Guide & Block - 2 Lengths |

| |

Stepper Motor (X & Y Axis) - Model | NEMA 34, Bipolar - Stepper Motor (Made in Japan) |

Stepper Motor (X & Y Axis) - Motor type | |

Stepper Motor (X & Y Axis) - No. of steps/rotation | |

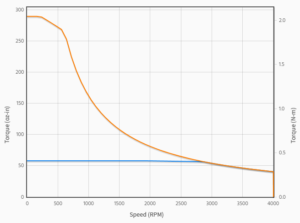

Stepper Motor (X & Y Axis) - Holding Torque | |

Stepper Motor (Z Axis) - Model | NEMA 34, Bipolar - Stepper Motor (Made in Japan) |

Stepper Motor (Z Axis) - Motor type | |

Stepper Motor (Z Axis) - No. of steps/rotation | |

Stepper Motor (Z Axis) - Holding Torque | |

Repeat Positioning Accuracy | |

Single Step Movement by Stepper | |

Stepper Motor Drivers - Max Current | |

Stepper Motor Drivers - Voltage Input | |

| |

| |

Stock / Material Fixturing Support | Aluminium - M5 T-slot Profiles - Pre-installed |

| Simultaneous 3 Axis Motion - Full Interpolation |

| |

| Three Phase Input Required |

| 16 Amp Plug Point Required |

| |

| |

| Ships Fully Assembled with selected accessories |

| Certified for 24/7 Operations |

| 1 Year Warranty - All Parts Covered |

| Up to 10 Years Extended Warranty - Optional |

| Annual Maintenance Contracts - Optional |

| |

| Fully compliant with GCODE / MCODE (GRBL) |

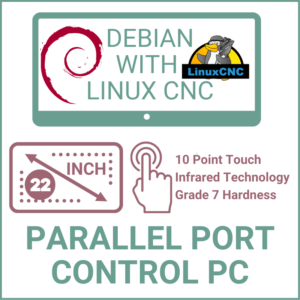

| Windows XP (64 bit), 7, 8, 10, 11, MacOS X, Linux (any), Raspberry Pi / ARM |

Minimum Control PC Specification | 2GB of RAM and a 1280 x 768 screen size |

Recommended Control PC Specification | 8GB of RAM, Intel 8th Gen Processor / AMD Zen 3 Architecture Processor & a minimum 1280 x 768 screen size |

Included PC Specifications | 16GB of RAM, AMD 3200G Processor, 256 GB SSD, 22 Inch FullHD Monitor |

Metric / Imperial Support | Supports Both MM & Inches |

| All of our measurements are made with Mitutoyo calibrated instruments |

| |