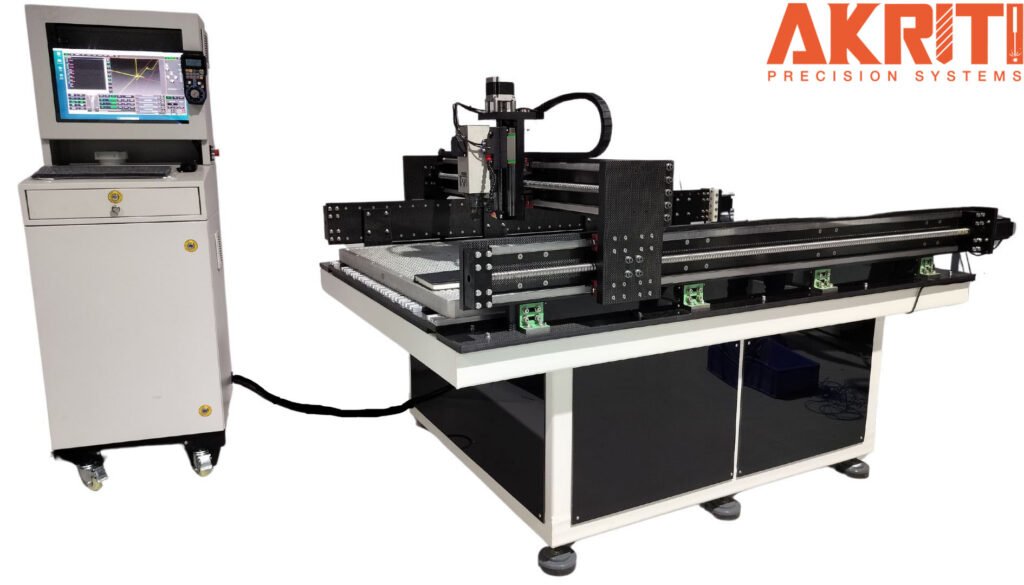

CNC (Computer Numerical Control) machines are the backbone of modern manufacturing, and Akriti Precision Systems, based in Bangalore, India, stands out as a key player in the production of high-quality parts for CNC machines. What makes Akriti Precision Systems unique is their strategic sourcing of parts, with approximately 75% of components coming directly from Indian manufacturers and the rest from top-tier, quality-conscious suppliers in Italy, Germany, Japan, Taiwan, Korea, and France. This blend of local and international sourcing ensures that the CNC machines they produce are both affordable and world-class, maintaining exceptional performance standards.

The Significance of Sourcing Quality Parts Locally

India has emerged as a significant hub for the production of industrial machinery components, and Akriti Precision Systems is deeply committed to supporting the local supply chain. By sourcing about 75% of the parts for CNC machines from Indian manufacturers, Akriti Precision Systems ensures not only cost-effectiveness but also fosters growth within the local economy. Indian manufacturers have made tremendous strides in precision engineering, producing components that meet the strict standards required for high-performance CNC machines.

These local suppliers are carefully vetted to ensure that every component meets the specifications and tolerances necessary for CNC machines to operate smoothly. Parts such as bearings, precision shafts, tool holders, and spindle components come from trusted Indian manufacturers, helping reduce lead times and improving supply chain efficiency. Furthermore, with the majority of parts being sourced from nearby suppliers, Akriti Precision Systems can pass on the benefits of competitive pricing to their customers without compromising on quality.

Why International Sourcing is Key for Specialized Components

While Indian suppliers provide the bulk of the components, Akriti Precision Systems also recognizes the need for certain specialized parts that require sourcing from international markets known for their technological expertise. Approximately 25% of the parts for CNC machines come from globally renowned suppliers in Italy, Germany, Japan, Taiwan, Korea, and France. These countries have a long-standing reputation for producing high-precision machine parts, often leading the world in CNC technology innovation.

For example, spindle drives, high-performance electronic controllers, and advanced tool holding systems are sourced from Germany and Japan, where companies have decades of experience in developing cutting-edge CNC technology. Italy and France are known for precision gear systems and ball screws, while Taiwan and Korea excel in providing high-quality linear motion guides and bearings. The combination of these international components with Indian-made parts allows Akriti Precision Systems to produce CNC machines that not only meet but exceed global standards.

Importance of High-Quality Parts for CNC Machine Longevity

One of the key factors that determine the lifespan and performance of any CNC machine is the quality of its components. High-quality parts ensure that the machine can perform repetitive tasks with precision and reliability. CNC machines operate in environments where accuracy is paramount, often cutting, drilling, or shaping materials down to tolerances as fine as a micron. Any deviation due to substandard parts could lead to significant defects in the final product, wasting time, materials, and resources.

Akriti Precision Systems understands the critical role that precision-engineered parts play in ensuring that their CNC machines deliver long-lasting, high-quality performance. Bearings, spindles, and linear motion components need to resist wear and tear, especially in high-speed, high-load applications. Poor-quality parts could lead to breakdowns, unscheduled downtime, and costly repairs. By sourcing the best possible parts both locally and internationally, Akriti Precision Systems guarantees that their CNC machines run smoothly, reduce maintenance needs, and last longer than those using inferior components.

Precision Parts and the Role of Tolerances

Another important aspect of using high-quality parts is maintaining tight tolerances, which are critical to the functionality of CNC machines. Tolerances define how much variation is allowed in the machine’s performance and operation. For example, if a ball screw is manufactured outside of its specified tolerance, it could lead to inaccuracies in motion, which, in turn, would compromise the quality of the final machined part.

At Akriti Precision Systems, every part for CNC machines undergoes rigorous quality control measures to ensure they conform to the required tolerances. Components such as spindles and bearings are tested under various load conditions to ensure that they will not deviate from their specifications even after prolonged use. This dedication to precision ensures that each CNC machine produced by Akriti Precision Systems is capable of delivering consistent, high-quality performance over time.

Durability and the Role of Materials in CNC Parts

The durability of CNC machines is heavily influenced by the materials used in their components. Parts such as tool holders, spindles, and gear systems are subjected to significant forces and must be made from materials that can withstand wear, corrosion, and heat. Akriti Precision Systems places a strong emphasis on sourcing components made from high-grade materials such as hardened steel, ceramic composites, and tungsten alloys, all of which enhance the longevity of their machines.

By choosing suppliers from both India and abroad who are known for producing components from these advanced materials, Akriti Precision Systems ensures that their CNC machines remain durable, even in demanding industrial environments. This results in fewer breakdowns, lower long-term costs, and better overall machine performance.

The Future of CNC Parts Sourcing at Akriti Precision Systems

Akriti Precision Systems is continually evaluating its sourcing strategies to ensure that they remain competitive in the global market. By maintaining a strong local supply chain in India, they are able to meet rising demand for affordable and high-performance CNC machines. At the same time, their partnerships with internationally renowned suppliers allow them to incorporate cutting-edge technology into their machines.

Moving forward, Akriti Precision Systems aims to increase the efficiency of their supply chain even further, reducing lead times while continuing to source the highest quality parts for CNC machines. Their commitment to quality is evident in the careful selection of every component, whether sourced locally or from abroad.

Conclusion: A Global Approach to High-Quality CNC Machine Parts

In conclusion, the sourcing strategy of Akriti Precision Systems is a perfect example of how a company can leverage both local and global resources to create superior products. By sourcing approximately 75% of the parts for CNC machines from Indian manufacturers and the remaining 25% from quality-conscious companies in Italy, Germany, Japan, Taiwan, Korea, and France, Akriti Precision Systems has struck the right balance between affordability and excellence. Their approach ensures that their CNC machines are built to last, providing reliable, precise, and efficient performance for years to come.