Introduction

The rise of small-scale manufacturing and the maker movement has opened new avenues for entrepreneurs to make money with a CNC Machine with limited capital. Among the most exciting opportunities is using a CNC (Computer Numerical Control) machine, particularly when working with metals like aluminum, brass, copper, and bronze. These materials are in high demand across various industries, from aerospace to jewelry design, providing a wealth of opportunities for those with the right skills and tools.

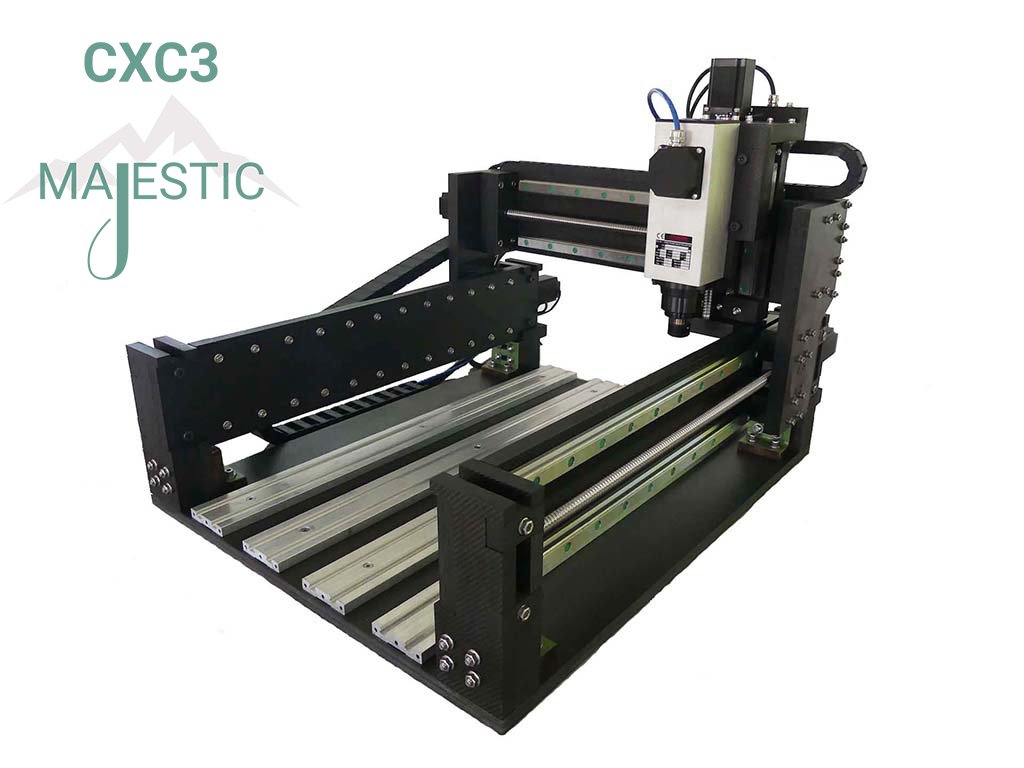

This article explores how you can Make Money with a CNC Machine by turning your CNC machining skills into a profitable venture, with a special focus on the CXC3 Majestic Series of CNC machines from Akriti Precision Systems, Bangalore. These advanced machines offer unparalleled precision, speed, and versatility, making them ideal for entrepreneurs looking to make their mark in the manufacturing industry.

Understanding the Market for Aluminium, Brass, Copper, and Bronze Products

The Versatility of Non-Ferrous Metals

Aluminum, brass, copper, and bronze are some of the most versatile materials in manufacturing. Each of these metals has unique properties that make them suitable for various applications:

- Aluminum: Lightweight, corrosion-resistant, and easy to machine, aluminum is widely used in industries ranging from automotive to consumer electronics.

- Brass: Known for its aesthetic appeal and acoustic properties, brass is often used in decorative items, musical instruments, and plumbing fixtures.

- Copper: Highly conductive and antimicrobial, copper is essential in electrical components, plumbing, and medical devices.

- Bronze: Valued for its hardness and wear resistance, bronze is used in bearings, bushings, and sculptures.

These metals’ widespread applications make them ideal for producing high-value products with a CNC machine. The market demand for customized parts, intricate designs, and small batch production ensures a steady stream of potential customers.

Target Industries

To effectively capitalize on the potential of these metals, it’s essential to understand the industries where they are most in demand:

- Aerospace and Defense: Aluminum and copper components are crucial in aerospace due to their strength-to-weight ratio and conductivity.

- Automotive: Brass and bronze parts are often used in engines, transmissions, and decorative trims.

- Electronics: Copper’s excellent conductivity makes it indispensable in manufacturing circuit boards and connectors.

- Art and Design: Brass and bronze are popular choices for sculptures, jewelry, and other artistic creations.

Identifying your niche within these industries can help you tailor your offerings and market your products effectively.

Starting a CNC Machining Business: Key Considerations

Investment in Equipment

Starting a CNC machining business requires a significant initial investment in equipment. The choice of machine can make or break your business, as it directly affects the quality and efficiency of your production processes. This is where the CXC3 Majestic Series from Akriti Precision Systems comes into play.

The CXC3 Majestic Series: A Game-Changer for Small Businesses

The CXC3 Majestic Series is a range of high-performance CNC machines designed to meet the needs of small to medium-sized enterprises. Here’s why these machines stand out:

- Precision: The CXC3 Majestic Series offers standard accuracy of <50 microns repeat positioning accuracy, ensuring that even the most intricate designs are executed flawlessly. This level of accuracy is crucial when working with metals like brass and bronze, where detail is paramount.

- Speed: These machines are equipped with high-speed electro-spindles and rapid feed rates, allowing you to complete jobs faster without sacrificing quality. This is particularly beneficial in a competitive market where turnaround time can be a deciding factor.

- Versatility: Whether you’re milling, drilling, or engraving, the CXC3 Majestic Series can handle it all. Its versatility means you can diversify your product offerings, from functional components to decorative items.

- Ease of Use: Despite its advanced capabilities, the CXC3 Majestic Series is user-friendly, making it accessible even to those new to CNC machining. Akriti Precision Systems also provides extensive training and support, ensuring you can maximize your machine’s potential.

Setting Up Your Workspace

Once you’ve invested in the right equipment, setting up a workspace that fosters efficiency and safety is essential. Consider the following:

- Space Requirements: Ensure you have enough space to accommodate the machine, raw materials, and finished products. The CXC3 Majestic Series is designed with a compact footprint, making it suitable for smaller workshops.

- Ventilation and Dust Collection: Machining metals can generate dust and fumes, so proper ventilation and dust collection systems are necessary to maintain a safe working environment.

- Tool Storage: Organize your tools and accessories efficiently to minimize downtime during production.

Sourcing Materials

To produce high-quality products, you’ll need a reliable source of raw materials. Establish relationships with suppliers who can provide consistent quality at competitive prices. Consider factors such as:

- Material Grade: Different applications require different material grades. Ensure you understand the specific requirements of your target market.

- Lead Time: A reliable supplier should be able to deliver materials within the required time frame to avoid production delays.

- Cost: Compare prices from multiple suppliers to ensure you’re getting the best deal without compromising on quality.

Profitability Strategies: Maximizing Returns from CNC Machining

Customization and Niche Markets

One of the significant advantages of CNC machining is the ability to produce customized products tailored to the specific needs of your customers. By focusing on niche markets, you can command higher prices for unique, made-to-order items. Here’s how you can tap into this:

- Personalized Products: Offer engraving services or custom designs for industries like jewelry, where unique items are highly valued.

- Small Batch Production: Cater to businesses that need low-volume production runs, which are often overlooked by larger manufacturers.

- Prototyping Services: Provide rapid prototyping services for engineers and designers who need to test their concepts before mass production.

Marketing Your CNC Machining Business

No matter how good your products are, you won’t succeed without effective marketing. Here are some strategies to help you reach potential customers:

- Online Presence: Create a professional website showcasing your services and past projects. Use SEO (Search Engine Optimization) techniques to attract organic traffic.

- Social Media: Platforms like Instagram and LinkedIn are excellent for sharing photos of your work and connecting with potential clients.

- Networking: Attend industry events and trade shows to network with potential customers and suppliers. Word-of-mouth referrals can be a powerful marketing tool.

- Partnerships: Partner with designers, engineers, and other professionals who might require CNC machining services, creating a steady stream of referrals.

FAQs

1. What is the cost of a CXC3 Majestic Series CNC machine?

- The cost varies depending on the specific model and configuration. Contact Akriti Precision Systems directly for a customized quote.

2. Can I use the CXC3 Majestic Series for materials other than aluminum, brass, copper, and bronze?

- Yes, the CXC3 Majestic Series is versatile and can handle a wide range of non-ferrous metals & materials, including plastics, acrylic, composites, wood, mdf, zinc, nickel, mica etc.

3. Is training provided when purchasing a CXC3 Majestic Series machine?

- Akriti Precision Systems offers 2 days of training to ensure you can operate the machine effectively and maximize its potential. Contact Akriti for more details.

4. How do I maintain the CXC3 Majestic Series machine?

- Regular maintenance includes cleaning, lubrication, and software updates. Akriti Precision Systems will support you in maintaining your machines for long durations.

5. What industries can benefit from CNC machining with non-ferrous metals?

- Industries such as aerospace, automotive, electronics, and art and design can significantly benefit from CNC machining of non-ferrous metals like aluminum, brass, copper, and bronze.

6. Can I start a CNC machining business from home?

- Yes, many entrepreneurs start their CNC machining businesses from home. However, you’ll need to consider space, noise, and safety factors.

Conclusion

Starting a CNC machining business focused on aluminum, brass, copper, and bronze offers a wealth of opportunities in today’s market. With the right equipment, like the CXC3 Majestic Series from Akriti Precision Systems, and a solid business plan, you can turn your machining skills into a profitable venture. Whether you’re producing customized components or entering niche markets, the precision, speed, and versatility of the CXC3 Majestic Series will help you achieve your entrepreneurial dreams.