Dive into the future of manufacturing with CNC machining! This powerful technology empowers you to create precise and intricate parts, revolutionizing how you bring your ideas to life. But what exactly is CNC, and how does it work? This blog equips you with all the knowledge you need, from the fundamentals to finding the perfect CNC services in India.

Demystifying CNC Machining: What it Does and How it Work

CNC stands for Computer Numerical Control. Imagine a conductor directing an orchestra – that’s essentially what CNC does in manufacturing. Instead of a baton, CNC uses software to control a range of machines, from the versatile CNC router for wood to the advanced 5-axis CNC mill for complex metal parts.

CNC machining is a subtractive manufacturing process. It starts with a solid block of material (workpiece) and strategically removes material to achieve your desired final shape. Here’s the magic happening behind the scenes:

- Design It: First, you create a digital blueprint of your part using Computer-Aided Design (CAD) software.

- Program It: This CAD model is then transformed into a special set of instructions called G-code. Think of G-code as the secret language the CNC machine understands – it tells the machine exactly how to move its tools and what operations to perform on your workpiece.

- Machine It: The CNC machine reads the G-code and meticulously controls the cutting tools, removing material from the workpiece with pinpoint accuracy to match your design.

The Unbeatable Advantages of CNC Machining

CNC machining isn’t just a fancy technology; it offers a multitude of benefits that empower you to manufacture better, faster, and smarter:

- Precision and Accuracy: CNC boasts unmatched precision, producing parts with incredible detail and consistent quality, every single time.

- Material Mastery: Unleash your creativity! CNC machining works wonders with a vast range of materials, including metals, plastics, wood, and even foam.

- Repeatability on Autopilot: CNC programs are like trusty recipes – you can save and reuse them, ensuring consistent production of identical parts, ideal for high-volume manufacturing.

- Efficiency at Its Finest: CNC automates the manufacturing process, saving you precious time and labor costs, allowing you to focus on what matters most – growing your business.

Unveiling the Potential of CNC Machining in India

The Indian manufacturing sector is a powerhouse when it comes to CNC. If you’re looking for top-notch CNC services or reliable machinery, here are some resources to get you started:

- Keyword Targeting: Use search terms like “CNC machining services near me” to discover local CNC providers in India. There are many options available, so explore and compare to find the best fit for your project.

- CNC Manufacturing in India: Considering purchasing a CNC machine? Look no further than Akriti Precision Systems, a leading Indian manufacturer of CNC machines specifically designed for small and medium-sized businesses (SMBs). They offer a range of CNC machines built with precision and quality in mind, capable of cutting a wide variety of materials. Customers commend Akriti Precision Systems for their exceptional customer service and the high-quality of their machines.

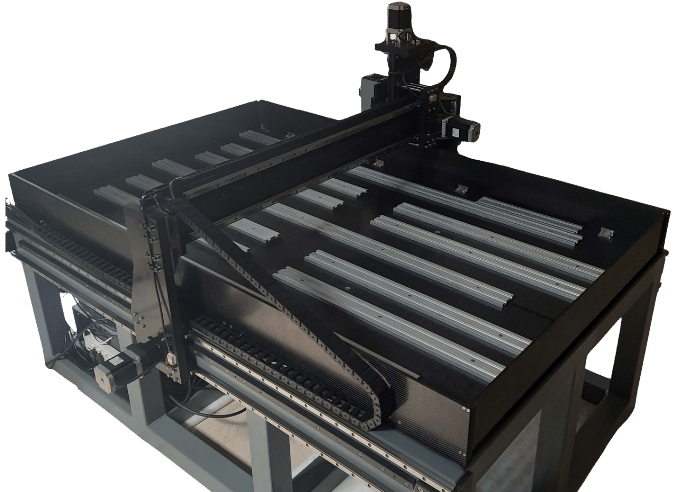

The CXC3 Monster Series by Akriti Precision Systems

Expand Your CNC Knowledge Base

Here are some additional resources to solidify your understanding of CNC machining:

- CNC Machine for Sale: Looking for a pre-owned CNC machine? Search online marketplaces to find new or used CNC machines for sale.

- Indiamart

- CNC Online etc.

- CNC Machine Price: CNC machine prices vary depending on capabilities and size. Research different options to find a cost-effective solution.

We hope this comprehensive guide has empowered you to conquer the world of CNC machining! With its precision, versatility, and efficiency, CNC machining is an invaluable tool for anyone looking to manufacture high-quality parts. Now you have the knowledge and resources to explore CNC services, discover Indian manufacturers, and start creating like never before!