In the rapidly evolving manufacturing industry, precision and efficiency are vital factors that can make or break a business. This is where Computer Numerical Control (CNC) machines come into play. CNC machines have revolutionized manufacturing processes by offering unparalleled accuracy and increased productivity. These machines utilize computer-aided design (CAD) software to control and manipulate various tools and equipment, allowing for the creation of complex and intricate parts with exceptional precision. From milling machines to lathes, there is a wide range of CNC types available, each with its specific function and capabilities. Whether you are in the automotive, aerospace, or medical device industry, understanding the different types of CNC machines can help you optimize your manufacturing process and drive growth. In this article, we will delve into the various types of CNC machines, exploring their functionalities, benefits, and industries they are best suited for. We will uncover the advantages of using CNC machines, such as faster production, reduced waste, and improved quality control. Join us as we take a deep dive into the world of CNC machines and see how they can enhance precision and efficiency in the manufacturing industry.”

1) Understanding the Importance of Precision and Efficiency in Manufacturing

Precision and efficiency are the cornerstones of modern manufacturing. Today’s industries demand fast, accurate, and repeatable processes to meet high production standards. CNC machines have emerged as a critical solution, enabling manufacturers to create intricate and precise parts at high speeds. This is particularly important in industries such as automotive, aerospace, and electronics, where even the smallest errors can have significant consequences.

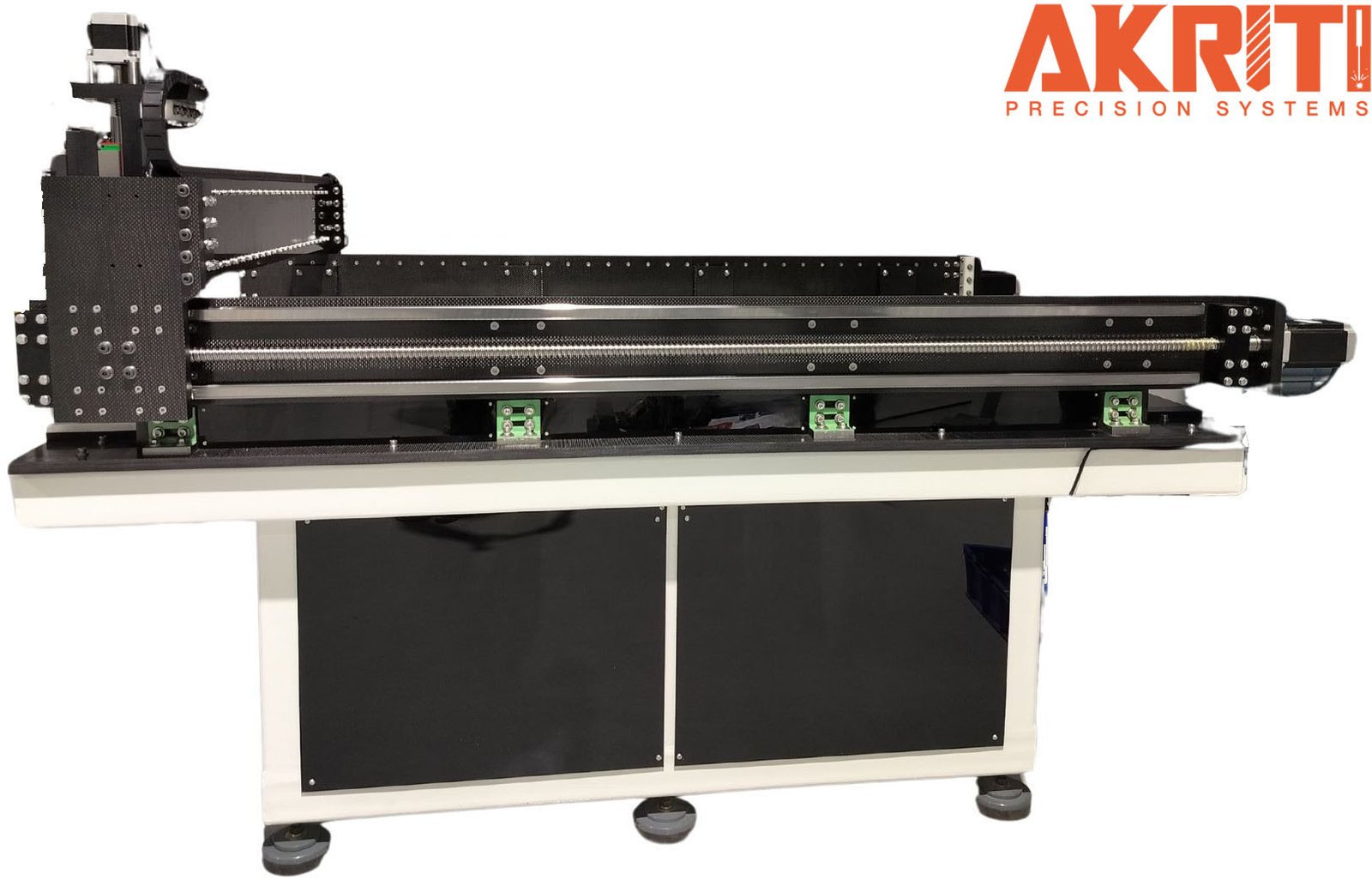

As an Indian CNC Machine Manufacturer, Akriti Precision Systems in Bangalore has been at the forefront of delivering machines that meet these high standards. By using advanced technology and sourcing 75% of their components from local Indian manufacturers, they ensure their machines are reliable, cost-effective, and tailored to meet the specific needs of various industries. The remaining 25% of parts are sourced from top-quality suppliers in Italy, Germany, Japan, Taiwan, Korea, and France, enhancing their machines’ precision and efficiency.

2) Types of CNC Machines and Their Applications

There are numerous CNC types available, each designed to perform specific tasks with extreme accuracy. Some of the most common CNC machines include:

- CNC milling machines – Used for drilling and cutting materials.

- CNC lathe machines – Ideal for turning operations.

- CNC plasma cutting machines – Specializes in cutting metal sheets.

- CNC routers – Best for woodworking, engraving, and cutting softer materials.

- CNC laser cutting machines – Suitable for cutting with fine precision.

- CNC wire EDM machines – For creating complex shapes with high accuracy.

Each CNC type serves a distinct purpose, helping manufacturers in different industries optimize their production processes.

3) CNC Milling Machines: Features and Advantages

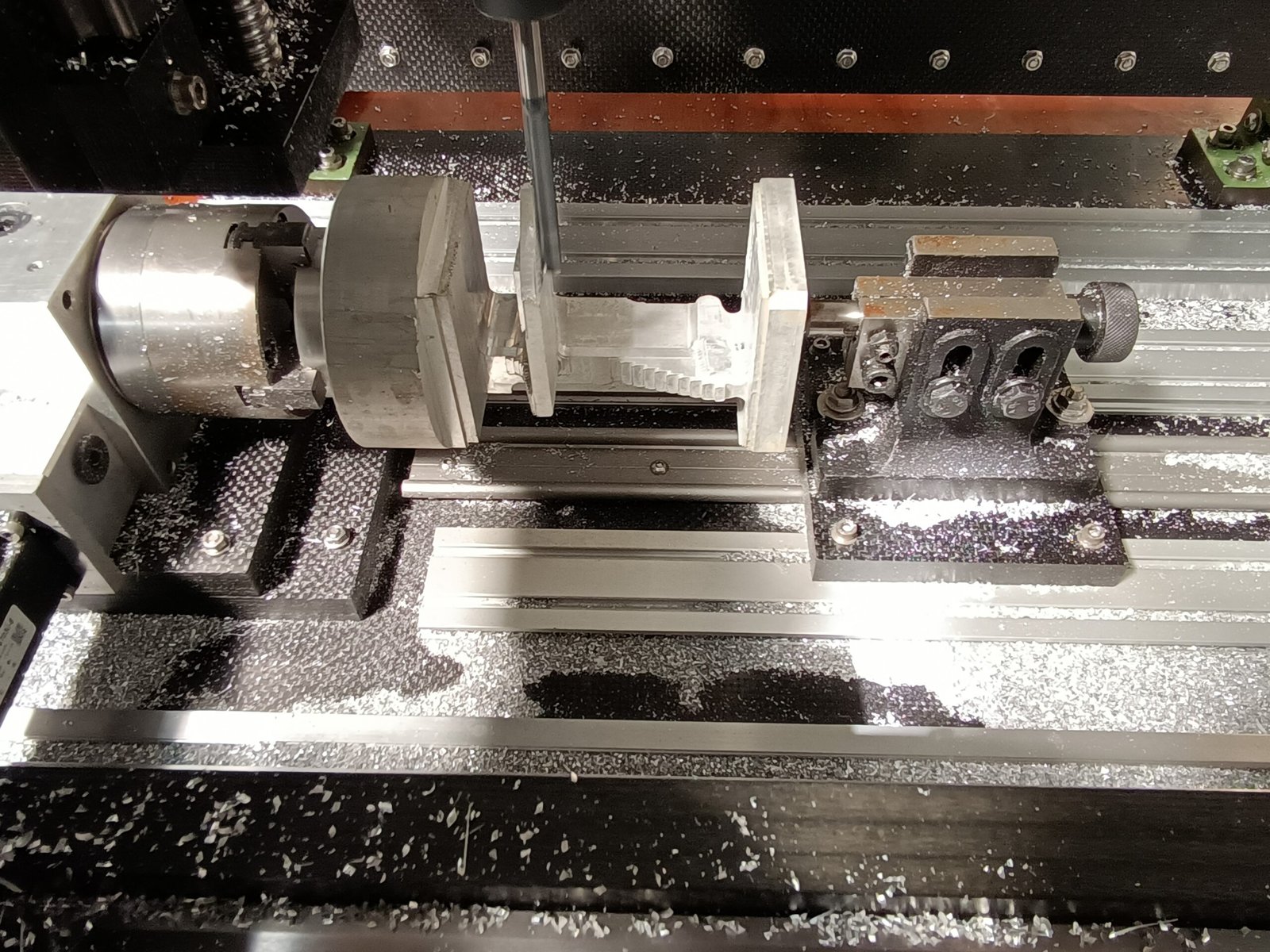

CNC milling machines are versatile tools capable of cutting, drilling, and shaping materials with high precision. They are often used in industries like automotive, aerospace, and manufacturing, where the production of complex parts is essential. With a CNC milling machine, operators can produce components with tight tolerances, ensuring consistency across large production runs.

Akriti Precision Systems, a leading Indian CNC Machine Manufacturer, produces CNC milling machines that are highly regarded for their durability and accuracy. These machines utilize locally sourced components and advanced technology to deliver outstanding performance. The addition of imported parts from Italy and Germany further enhances their quality, ensuring smooth and efficient operations.

4) CNC Lathe Machines: Enhancing Precision in Turning Operations

CNC lathe machines specialize in rotating a workpiece while a cutting tool is applied to shape it. This is particularly useful for creating cylindrical parts, such as shafts, bolts, and screws. These machines are known for their precision in turning operations and are widely used in industries that require detailed, accurate components.

5) CNC Plasma Cutting Machines: A Cost-Effective Solution for Metal Fabrication

CNC plasma cutting machines are used for cutting metal sheets and plates with precision. By utilizing an electrically conductive gas to cut through metal, these machines offer a cost-effective solution for fabricators working with various metals, such as steel and aluminum.

6) CNC Routers: Versatile Machines for Woodworking and Engraving

CNC routers are highly flexible machines designed for cutting and engraving wood, plastic, and other softer materials. They are widely used in industries like furniture manufacturing, signage, and decorative design, where intricate patterns and shapes are required.

Akriti Precision Systems offers CNC routers that are engineered to deliver precision and speed, making them ideal for a wide range of applications. As an Indian CNC Machine Manufacturer, Akriti’s focus on local manufacturing ensures their routers are well-suited for businesses seeking both affordability and advanced capabilities.

7) CNC Laser Cutting Machines: High-Precision Cutting for Various Materials

CNC laser cutting machines use high-powered lasers to cut through a variety of materials, such as metal, plastic, and wood. These machines are favored for their ability to achieve fine, clean cuts without the need for extensive finishing work.

8) CNC Wire EDM Machines: Precision Machining for Complex Shapes

CNC wire EDM (Electrical Discharge Machining) machines are used to create complex shapes by cutting through hard materials with an electrically charged wire. This type of CNC machine is crucial in industries like aerospace and tool making, where precision and intricacy are vital.

9) Conclusion: The Future of CNC Machines in Manufacturing

The future of CNC machines is promising, with advancements in technology driving further improvements in precision, speed, and efficiency. Companies like Akriti Precision Systems, an Indian CNC Machine Manufacturer, are leading the way by combining local manufacturing with top-quality imported components from global leaders in CNC technology. This approach not only reduces costs but also ensures that manufacturers have access to reliable and innovative CNC machines.

As industries continue to evolve, CNC machines will play an increasingly important role in helping manufacturers stay competitive by enhancing precision, reducing waste, and boosting overall productivity. Understanding the different CNC types available and their applications can help businesses optimize their processes and position themselves for long-term success.