1. Introduction to CNC Routing & Design Making in Wood

CNC routing & Design has revolutionized the world of woodworking, allowing artisans and businesses to create intricate designs with unparalleled precision. In woodworking, CNC (Computer Numerical Control) technology refers to the automation of machine tools, such as routers, via computer systems. This technology has evolved significantly, making it an indispensable tool for modern woodworkers. By enabling complex cuts and shapes that were previously impossible or time-consuming, CNC routing & design (2D & 3D) have opened new avenues for creativity and efficiency.

2. Importance of CNC Machines in Modern Woodworking

CNC machines have become crucial in woodworking due to their precision and ability to replicate designs consistently. Unlike traditional methods, CNC routing provides a high level of accuracy, ensuring that each piece is cut to exact specifications. This not only improves the quality of the finished product but also saves time, enhancing productivity and profitability for woodworking businesses.

3. Overview of Akriti Precision Systems Private Limited

Based in Bangalore, India, Akriti Precision Systems Private Limited is renowned for its innovative CNC solutions. With a strong commitment to quality and customer satisfaction, the company intends to established itself as a leader in the CNC machine industry. Specializing in high-performance CNC machines, Akriti Precision Systems offers a range of products that cater to diverse woodworking needs.

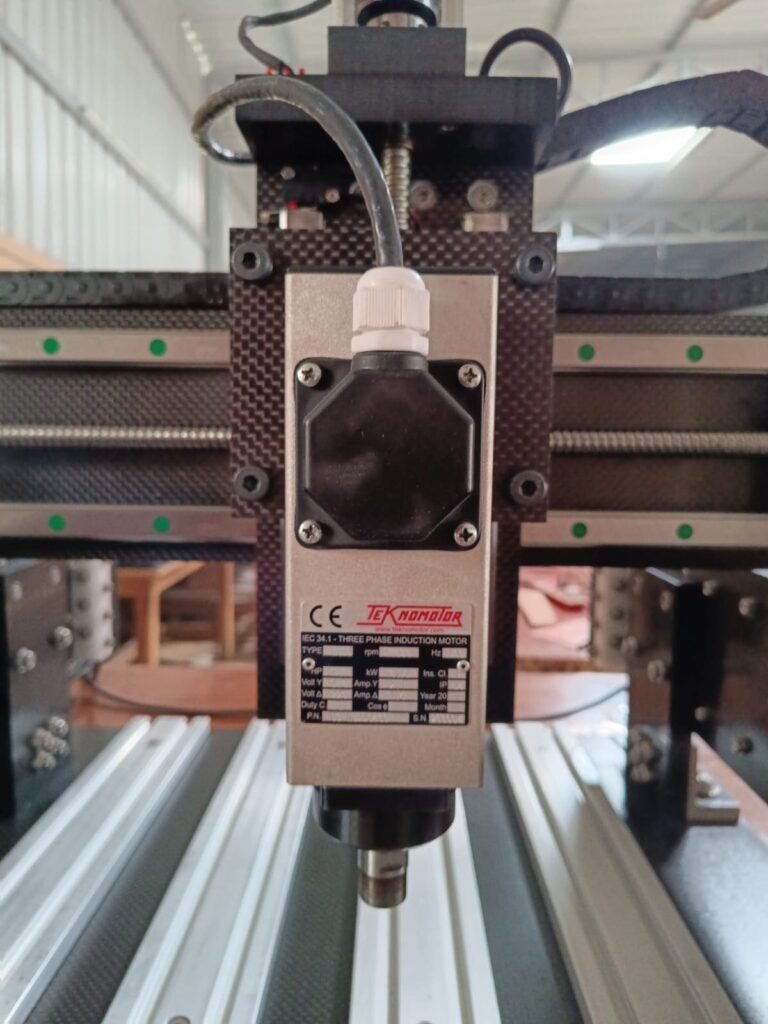

4. Introduction to CXC3 Mighty & CXC3 Mighty XL Series

Among their most prominent offerings are the CXC3 Mighty and CXC3 Mighty XL Series CNC machines. These machines are designed to provide full 3-axis operations, catering to various woodworking requirements. The CXC3 Mighty has a working size of 600×400 MM, while the Mighty XL offers a larger workspace of 900×600 MM. Both models deliver exceptional performance, reliability, and precision, making them ideal for both small-scale and large-scale woodworking projects.

5. Full 3-Axis Operations for Precision Routing

The CXC3 Mighty Series provides full 3-axis operations, which means it can move a cutting tool along three different axes (X, Y, and Z). This feature is crucial for creating complex wood designs with detailed curves, angles, and depths. The ability to maneuver along three axes allows for more intricate cuts, providing woodworkers with the flexibility to craft unique pieces that stand out.

6. Detailed Specifications of CXC3 Mighty

The CXC3 Mighty model is compact yet powerful, with a working size of 600×400 MM. It is designed to handle a variety of woodworking tasks, from crafting detailed furniture components to creating intricate art pieces. This machine is ideal for workshops that require a balance of size and capability. Its robust build ensures durability, while the precision of its cuts makes it perfect for detailed wood designs.

7. Detailed Specifications of CXC3 Mighty XL

For those who need a larger working area, the CXC3 Mighty XL provides a spacious 900×600 MM workspace. This expanded size accommodates bigger projects, such as larger furniture pieces or extensive panel designs. The Mighty XL retains all the benefits of the standard Mighty model, including high precision and reliability, but with the added advantage of a larger work surface, making it suitable for more substantial woodworking operations.

8. Unique Features of the CXC3 Mighty Series

The CXC3 Mighty Series stands out due to its combination of high-performance capabilities and user-friendly features. It is equipped with advanced software that integrates seamlessly with various design programs, allowing users to upload their designs easily. The machines also feature a sturdy build, designed to withstand the rigors of continuous operation, ensuring long-term reliability and consistent performance.

9. Advantages of Using CXC3 Mighty Series in Woodworking

Investing in the CXC3 Mighty Series can lead to significant cost savings and a strong return on investment. The machines’ efficiency reduces material waste, while their precision minimizes the need for rework. Additionally, the speed and accuracy provided by these CNC routers allow businesses to increase their production output without compromising quality.

10. Applications of CNC Routing in Woodworking

CNC routing is widely used in various woodworking applications, such as furniture making, cabinetry, and decorative wood art. With the CXC3 Mighty Series, users can create everything from detailed inlays and moldings to custom furniture and cabinetry components. The versatility of these machines makes them a valuable asset for any woodworking shop, whether for commercial production or custom art projects.

11. CXC3 Series in Action: Real-World Applications

Several woodworking shops and artists have successfully implemented the CXC3 Mighty Series into their production lines. These machines have proven to be invaluable for creating complex wood designs with speed and precision. Testimonials from satisfied customers highlight the reliability and ease of use of these CNC routers, showcasing their role in elevating woodworking craftsmanship.

12. How to Choose the Right CNC Machine for Woodworking

When selecting a CNC machine for woodworking, consider factors like size, power, software compatibility, and cost. The CXC3 Mighty Series stands out in the market due to its compact size, robust capabilities, and competitive pricing. For those looking to balance precision, size, and budget, the CXC3 Mighty models offer an ideal solution.

13. Future of CNC Routing in Woodworking

The future of CNC routing & designs in woodworking looks promising, with continuous advancements in technology enhancing precision, speed, and capabilities. Companies like Akriti Precision Systems are at the forefront of these innovations, constantly improving their machines to meet the evolving needs of the woodworking industry.

14. Maintenance and Support for CXC3 Mighty Machines

To maintain the efficiency and longevity of CNC machines like the CXC3 Mighty Series, regular maintenance is crucial. Akriti Precision Systems offers comprehensive support and after-sales service, ensuring that their clients receive the assistance they need to keep their machines running smoothly.

15. Conclusion: Why Invest in CXC3 Mighty Series for Woodworking?

In conclusion, the CXC3 Mighty and CXC3 Mighty XL Series CNC machines by Akriti Precision Systems offer unparalleled precision, reliability, and value for money. Whether for small-scale businesses or large woodworking operations, these machines provide the tools needed to enhance productivity and craftsmanship.

16. Frequently Asked Questions (FAQs)

Q1: What is CNC routing in woodworking?

CNC routing in woodworking involves using automated machines to cut and shape wood based on computer-generated designs.

Q2: What makes the CXC3 Mighty Series unique?

The CXC3 Mighty Series offers full 3-axis operations, compact design, and precision routing, making it suitable for a wide range of woodworking applications.

Q3: How does a 3-axis CNC machine benefit woodworking?

A 3-axis CNC machine allows for detailed and complex cuts, providing greater flexibility and precision in wood designs.

Q4: What are the sizes available for the CXC3 Mighty Series?

The CXC3 Mighty comes in a 600×400 MM size, while the CXC3 Mighty XL offers a larger 900×600 MM workspace.

Q5: Is the CXC3 Mighty Series suitable for small-scale businesses?

Yes, the compact size and affordability of the CXC3 Mighty Series make it an excellent choice for small-scale woodworking shops to do cnc routing & designs are avilable everywhere on the internet, some for free and some paid.

Q6: What kind of support does Akriti Precision Systems offer?

Akriti Precision Systems provides comprehensive after-sales support, ensuring that their customers receive the maintenance and assistance they need.