CNC (Computer Numerical Control) machines have revolutionized manufacturing processes across various industries. In engineering colleges, these advanced tools play a crucial role in educating future engineers and preparing them for real-world applications. Let’s explore the diverse use cases of CNC machines in engineering education.

1. Prototyping and Rapid Manufacturing

CNC machines allow students to create accurate prototypes of their designs. Whether it’s a mechanical part, an electronic enclosure, or a complex geometry, CNC machining ensures precision and consistency. Students can quickly iterate and refine their designs, gaining hands-on experience in the product development cycle.

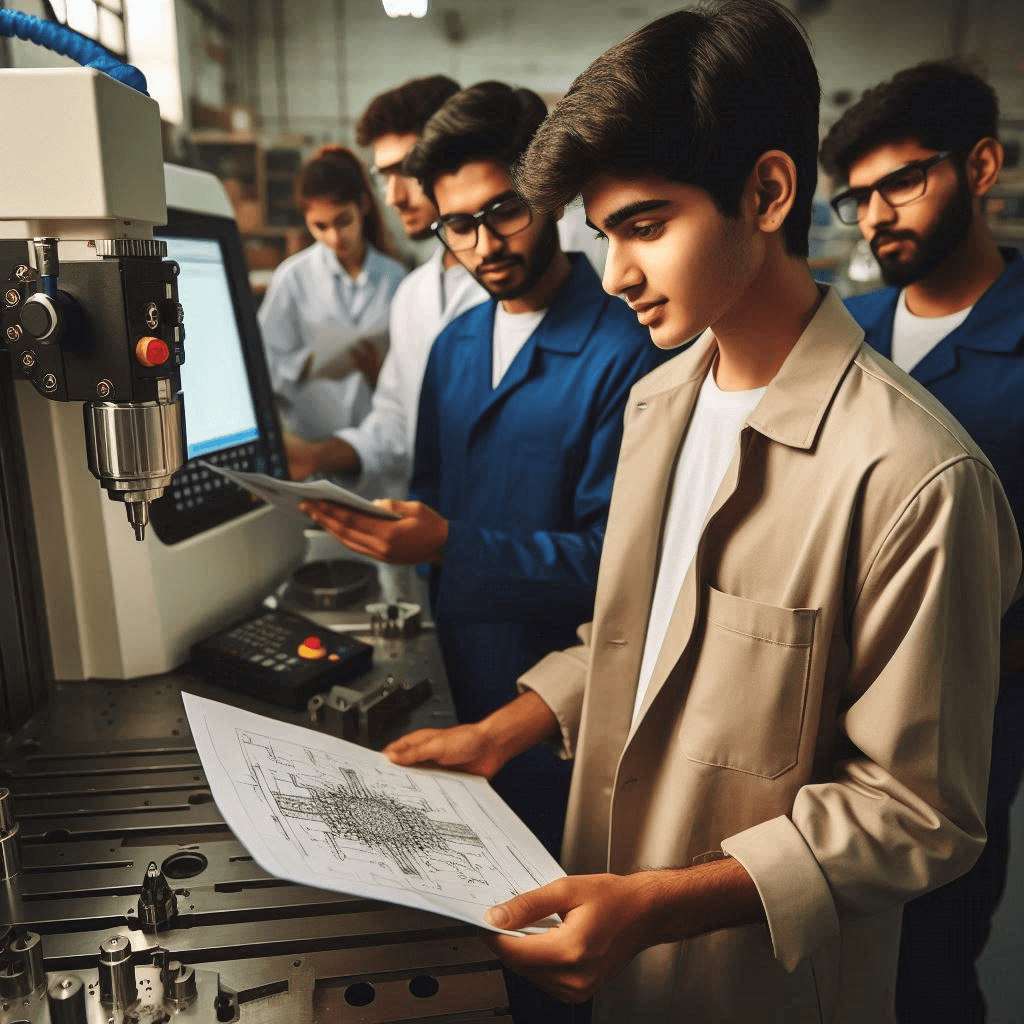

2. Educational Demonstrations

Engineering colleges use CNC machines as teaching aids during lectures and workshops. Professors demonstrate concepts related to machining, toolpaths, and material selection. Students observe the entire process, from CAD modeling to the finished part, enhancing their understanding of manufacturing principles.

3. Research and Development Projects

CNC machines facilitate research projects within engineering colleges. Students explore novel materials, investigate surface finishes, and optimize machining parameters. These projects contribute to scientific advancements and encourage innovation.

4. Student Competitions

Engineering colleges often participate in national and international competitions. CNC machining plays a vital role in events like Formula SAE, Baja SAE, and robotics competitions. Students design and manufacture components using CNC machines, showcasing their skills and teamwork.

5. Skill Development

Hands-on experience with CNC machines enhances students’ practical skills. They learn to program, set up, and operate these machines, gaining proficiency in G-code, tool selection, and workholding techniques. These skills are invaluable for their future careers.

High Precision and Unique Features of Akriti CNC Machines

Akriti Precision Systems, based in Bangalore, specializes in crafting top-notch 3 and 4-axis CNC machines. Here’s what sets them apart:

- Exceptional Precision: Akriti CNC machines offer default repeat positioning accuracy within 25-50 microns. For even tighter tolerances, upgrades are available, achieving precision as low as 3.5 microns. This level of accuracy ensures consistent results for critical applications.

- Non-Ferrous Material Expertise: Akriti machines excel in machining non-ferrous materials like aluminum, brass, and titanium. Their robust construction and specialized tooling allow precise cutting without compromising material integrity.

- Customizable Accessories: Recognizing that every workshop has unique needs, Akriti provides a comprehensive selection of compatible accessories. These expand machine capabilities and tailor them to specific workflows.

- Engineering Solutions: Akriti’s team collaborates with colleges to develop custom solutions. Whether integrating with existing processes or addressing specific challenges, their expertise ensures a smooth transition.

Conclusion

CNC machines empower engineering students by bridging theory and practice. Akriti Precision Systems’ commitment to precision and innovation makes them an ideal partner for colleges seeking cutting-edge CNC technology.

Ready to unlock the full potential of CNC machining? Explore Akriti’s product line at Akriti Precision Systems and elevate your metalworking projects!

Engineer, Beautiful !!