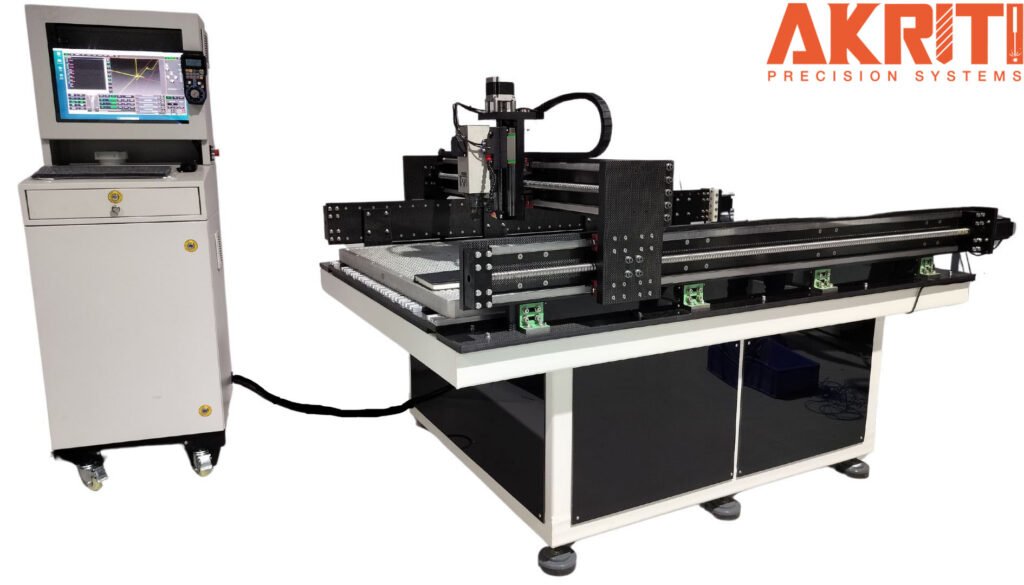

In the world of aerospace manufacturing, precision and efficiency are non-negotiable. Every component must meet strict specifications, as even the smallest deviation can compromise safety and performance. This is where CNC machines for the aerospace industry come into play, revolutionizing production processes by offering unparalleled accuracy and speed. At the forefront of this revolution is Akriti Precision Systems Private Limited, based in Bangalore, India. Known for its cutting-edge manufacturing solutions, Akriti has introduced the CXC3 Monster 64, a CNC machine designed specifically for non-ferrous applications such as aluminum, copper, brass, and bronze. With its 3-axis operations and a large 6 x 4 feet platform, the CXC3 Monster 64 sets new standards for precision in the aerospace sector.

Why Precision Matters in Aerospace Manufacturing

In aerospace manufacturing, achieving high precision is essential. Components often need to fit together perfectly, withstand extreme conditions, and perform reliably over long periods. Therefore, precision down to a few microns is not just a benefit—it’s a requirement. The CNC machines for the aerospace industry are tailored to meet these stringent standards, and Akriti Precision Systems is leading the charge by delivering machines that offer 3.5-micron accuracy. This level of precision ensures that every cut, drill, and shape is executed flawlessly, reducing errors and waste, and ultimately, improving overall efficiency.

Introducing the CXC3 Monster 64: A Game-Changer for Non-Ferrous Applications

The CXC3 Monster 64 by Akriti Precision Systems is specifically designed to handle non-ferrous materials like aluminum, copper, brass, and bronze. These materials are widely used in the aerospace industry due to their lightweight properties, corrosion resistance, and excellent strength-to-weight ratios. However, they also require specialized machining to maintain their integrity during the manufacturing process. The CXC3 Monster 64 excels in this area, offering full 3-axis operations on a robust 6 x 4 feet platform, which allows manufacturers to work on larger parts or multiple smaller components simultaneously.

Key Features of the CXC3 Monster 64

- Full 3-Axis Operations: The machine offers complete 3-axis CNC operations, providing a versatile solution for machining complex parts. This flexibility is crucial for aerospace manufacturers who need to produce a variety of components with intricate designs and tight tolerances.

- Large 6 x 4 Feet Platform: The sizable working area of the CXC3 Monster 64 allows for the machining of larger parts or multiple smaller parts in a single setup. This capability reduces downtime and increases throughput, making it a highly efficient solution for aerospace manufacturing.

- Precision of 3.5 Microns: Achieving an accuracy of 3.5 microns, the CXC3 Monster 64 ensures that every cut, drill, and shape is executed with exceptional precision. This level of accuracy is vital in the aerospace industry, where even a slight deviation can lead to significant problems down the line.

- Specialized for Non-Ferrous Applications: The machine is optimized for machining non-ferrous materials such as aluminum, copper, brass, and bronze. These materials require a different approach compared to ferrous metals, and the CXC3 Monster 64 is engineered to deliver optimal results in these applications.

How CNC Machines for Aerospace Industry Like the CXC3 Monster 64 Enhance Manufacturing Efficiency

Efficiency is another critical factor in aerospace manufacturing. With the CXC3 Monster 64, manufacturers can achieve higher productivity thanks to its advanced features and robust design. For instance, the large working platform and 3-axis capability allow for multiple operations in a single setup, significantly reducing the need for frequent tool changes and part repositioning. Additionally, the machine’s 3.5-micron accuracy minimizes the need for secondary operations like finishing or reworking, which further streamlines the manufacturing process.

Reducing Waste and Improving Sustainability

The precision of the CXC3 Monster 64 also plays a pivotal role in reducing material waste. In traditional machining processes, inaccuracies can lead to significant material wastage, especially when dealing with expensive non-ferrous materials. By delivering accurate results from the first cut, the CXC3 Monster 64 minimizes waste, helping aerospace manufacturers maintain sustainability while reducing costs.

The Role of Akriti Precision Systems in Advancing Aerospace Technology

Akriti Precision Systems Private Limited has established itself as a pioneer in precision engineering and manufacturing solutions. With a focus on developing high-quality CNC machines tailored for specific industries, Akriti continually pushes the boundaries of what is possible in machining technology. The CXC3 Monster 64 is a testament to their commitment to innovation, providing the aerospace sector with a machine that combines precision, efficiency, and reliability. This commitment ensures that CNC machines for the aerospace industry not only meet but exceed the evolving demands of modern aerospace manufacturing.

Benefits of Partnering with Akriti Precision Systems

- Expertise in Precision Engineering: With years of experience in the field, Akriti Precision Systems understands the unique challenges faced by aerospace manufacturers. Their expertise is evident in the design and functionality of the CXC3 Monster 64.

- Custom Solutions: Akriti offers tailored solutions to meet specific manufacturing needs, ensuring that each machine is optimized for its intended application. This customization is particularly valuable in the aerospace industry, where requirements can vary significantly from one project to another.

- Robust Customer Support: Akriti’s dedication to customer satisfaction extends beyond the sale of their machines. They provide comprehensive support and training to ensure that manufacturers can maximize the benefits of their CNC machines.

Embracing the Future of Aerospace Manufacturing with the CXC3 Monster 64

As the aerospace industry continues to evolve, the demand for precision, efficiency, and reliability in manufacturing will only grow. The CXC3 Monster 64 from Akriti Precision Systems stands out as a cutting-edge solution that meets these needs head-on. By leveraging the advanced capabilities of this CNC machine, aerospace manufacturers can achieve greater accuracy, reduce waste, and enhance their overall production processes. In doing so, they not only improve their bottom line but also contribute to the advancement of aerospace technology as a whole.

For those looking to master precision in aerospace manufacturing, the CXC3 Monster 64 offers a robust, reliable, and efficient solution. To learn more about this revolutionary machine and how it can benefit your operations, visit Akriti Precision Systems Private Limited.