In recent years, CNC (Computer Numerical Control) machines have revolutionized manufacturing by allowing for precise, automated control over complex machining tasks. Whether you’re an industry professional or a curious beginner, understanding the essential parts of a CNC machine is crucial to leveraging its full capabilities. In this guide, we’ll delve into the main components of CNC machines, covering everything from what is a stepper motor to control software options like Universal GCode Sender and Linux CNC.

Additionally, we’ll highlight the high-quality CNC machines produced by Akriti Precision Systems, an Indian CNC machine manufacturer based in Bangalore. Akriti’s machines boast a remarkable local content of over 75%, with some models reaching more than 90% indigenous parts. Let’s dive into the core elements that make CNC machines indispensable for modern manufacturing.

Table of Contents

- Introduction to CNC Machines

- Primary Parts of a CNC Machine

- Controller

- Stepper Motor

- Spindle

- Worktable

- Drive System

- What is Stepper Motor?

- Controller Software: Universal GCode Sender and Linux CNC

- About Akriti Precision Systems: Indian CNC Machine Manufacturer

- Types of CNC Machines by Akriti Precision Systems

- Advantages of High-Quality CNC Components

- FAQs

1. Introduction to CNC Machines

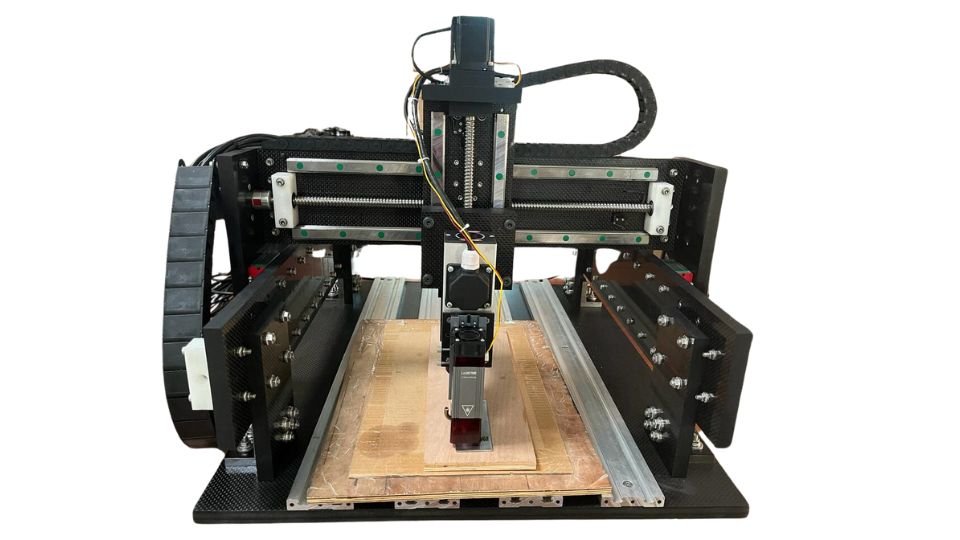

CNC machines automate tasks like cutting, milling, and drilling, which were previously performed manually. Through precise software-driven instructions, these machines can produce complex shapes and designs efficiently. This guide aims to clarify each essential component of a CNC machine, which collectively allow it to perform complex tasks with remarkable accuracy and speed.

2. Primary Parts of a CNC Machine

CNC machines comprise various essential parts that work in harmony to ensure optimal functionality. Below are the fundamental components you should know about:

Controller

The controller is the “brain” of a CNC machine, managing the machine’s movement by converting programmed commands into mechanical actions. The controller receives these instructions via software like Universal GCode Sender or Linux CNC, which are compatible with Akriti Precision Systems’ CNC models.

Stepper Motor

An essential component in every CNC machine, the stepper motor drives the machine’s axes by precisely rotating in small, controlled steps. This allows the machine to follow complex paths. Understanding what is a stepper motor is crucial, as its role in creating exact movements ensures that the final product meets stringent quality standards.

Spindle

The spindle is the rotating part that holds and powers the cutting tools. Its speed and power can vary depending on the machine’s requirements and the material being worked on.

Worktable

The worktable supports the material being machined. Depending on the CNC machine, the worktable might be adjustable to handle materials of different shapes and sizes.

Drive System

The drive system is responsible for the motion of the CNC machine’s axes. Stepper motors, lead screws, and ball screws work together within the drive system to execute precise, controlled movements based on the controller’s commands.

3. What is Stepper Motor?

A stepper motor is a core part of any CNC machine, responsible for precise positioning. It operates by moving in small steps, making it possible to perform detailed and intricate machining. In CNC machines, stepper motors are particularly valued for their ability to hold a position, ensuring the cutting tool doesn’t drift off-course. When asking “what is stepper motor” in the context of CNC machines, it’s essential to understand its role in achieving fine control over the toolpath.

These motors are especially significant in CNC machines by Akriti Precision Systems, which uses stepper motors from reliable manufacturers to maintain top-notch performance and precision in their products. Stepper motors in these machines handle various machining requirements, from simple cuts to complex, multi-axis operations.

4. Controller Software: Universal GCode Sender and Linux CNC

For smooth and accurate control of CNC machines, robust software is essential. Two of the most popular control software options include Universal GCode Sender and Linux CNC, both compatible with Akriti Precision Systems machines.

- Universal GCode Sender: This software is well-suited for hobbyists and professionals alike, as it provides an intuitive interface for sending GCode instructions. It’s popular for its versatility and ease of use, making it ideal for newcomers.

- Linux CNC: A powerful, open-source controller software, Linux CNC offers a wide array of features for more advanced users. Its flexibility and ability to handle complex machining tasks make it a preferred choice for industrial applications. With Linux CNC, users can manage intricate machining paths with ease.

These software tools help transform Akriti Precision Systems’ CNC machines into precise and user-friendly equipment, giving operators greater control over every cut.

5. About Akriti Precision Systems: Indian CNC Machine Manufacturer

As a notable Indian CNC machine manufacturer, Akriti Precision Systems is dedicated to high-quality, locally made CNC machines. Over 75% of their machines’ parts are indigenous, with certain models reaching up to 90% local content. The remaining components are carefully sourced from reputed suppliers in Italy, Germany, Japan, Taiwan, Korea, and France, ensuring only the highest standards.

Akriti Precision Systems specializes in various 3-axis CNC machines, which can also be converted into 2-in-1 models. These machines come with a full Lightburn license, adding to their versatility and value.

6. Types of CNC Machines by Akriti Precision Systems

Akriti Precision Systems manufactures various CNC machine models to serve diverse industries. The 3-axis CNC models are particularly versatile and can be upgraded to 2-in-1 configurations, making them suitable for various applications, from small workshops to large industrial settings. By offering customizable solutions, Akriti positions itself as a leading Indian CNC machine manufacturer.

7. Advantages of High-Quality CNC Components

High-quality CNC components ensure better performance, durability, and precision. Akriti Precision Systems incorporates over 75% indigenous parts into their machines, emphasizing reliability and local manufacturing prowess. Quality-conscious sourcing for the remaining components from countries like Italy, Germany, and Japan further enhances these machines’ standards, enabling them to handle rigorous manufacturing tasks.

8. FAQs

Q1: What is stepper motor in CNC machines? A stepper motor in CNC machines is a motor that moves in precise steps to control the machine’s axes, ensuring accuracy in every cut and movement.

Q2: Why is local content important in CNC machines? Local content reduces dependency on foreign suppliers and supports domestic manufacturing, while ensuring lower production costs and higher quality control.

Q3: How does Universal GCode Sender work with CNC machines? Universal GCode Sender translates GCode commands into movements, allowing CNC machines to execute complex instructions smoothly.

Q4: What is stepper motor’s role in achieving precision? A stepper motor’s ability to hold positions without drifting makes it ideal for CNC tasks that demand high accuracy.

Q5: Is Linux CNC suitable for beginners? While powerful, Linux CNC is generally more suited to users with some CNC experience due to its advanced capabilities.

Q6: What distinguishes Akriti Precision Systems as an Indian CNC machine manufacturer? Akriti’s commitment to using more than 75% indigenous content, along with high-quality imports for critical components, sets it apart in the CNC manufacturing space.

Conclusion

Understanding CNC machine parts—from stepper motors to spindle systems—is the first step to mastering these powerful tools. Whether you’re exploring what is stepper motor, learning about control software like Universal GCode Sender and Linux CNC, or choosing a reliable Indian CNC machine manufacturer, this guide has provided essential insights to get you started. For beginners and industry professionals alike, Akriti Precision Systems’ CNC machines offer unparalleled quality and versatility, making them a trusted choice in India and beyond.