In today’s fast-paced technological world, CNC machines have become essential in engineering education. The uses of CNC machines in engineering colleges extend far beyond traditional manufacturing practices. These machines not only help students develop hands-on skills but also bridge the gap between theoretical knowledge and real-world applications. With the growing emphasis on practical learning, CNC machines are becoming indispensable tools in modern engineering curricula.

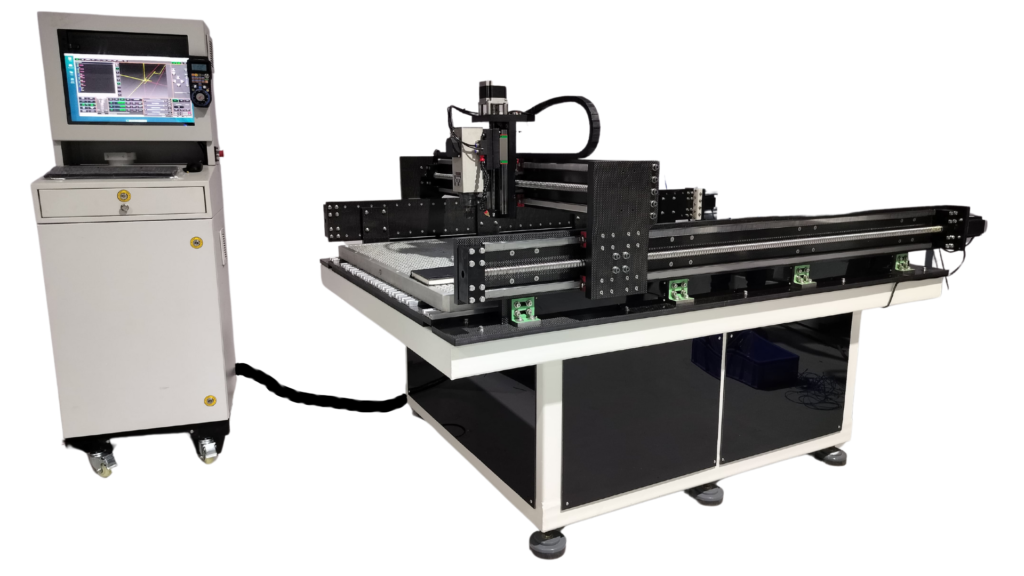

One notable provider in this space is Akriti Precision Systems, a leading Indian CNC Machine Manufacturer based in Bangalore, India. They produce high-quality CNC machines with around 75% of their parts made locally in India. The remaining parts come from trusted suppliers in countries such as Italy, Germany, Japan, Taiwan, Korea, and France. This balance of local manufacturing and international sourcing ensures superior quality and performance, making Akriti Precision Systems a key player in the CNC industry.

1. Enhancing Practical Learning

The most important use of CNC machines in engineering colleges is to enhance practical learning. Students can apply the theoretical concepts they learn in the classroom directly to real-life scenarios. CNC machines enable them to fabricate complex designs with precision, something that would be impossible using manual techniques. This hands-on experience makes the learning process more dynamic, engaging, and meaningful.

2. Promoting Innovation and Creativity

CNC machines give students the freedom to experiment and innovate. From creating intricate prototypes to developing custom tools, these machines unlock new levels of creativity. Instructors can encourage students to work on independent projects, furthering their understanding of design, programming, and material properties. As a result, engineering colleges can foster an environment where students feel inspired to push the boundaries of conventional engineering.

3. Preparing Students for Industry

Incorporating CNC machines into the engineering curriculum is crucial for preparing students for industry. Many manufacturing companies rely heavily on CNC technology for mass production and custom manufacturing. Familiarizing students with this technology gives them an edge in the job market. Moreover, industry-oriented CNC machines, such as those made by Akriti Precision Systems, replicate the exact tools used in professional environments, ensuring students gain relevant and valuable experience.

4. Precision and Accuracy in Prototyping

Another important use of CNC machines is in the area of prototyping. Engineering students often need to create models to test their designs. CNC machines offer unparalleled precision, allowing students to fabricate parts and prototypes to exact specifications. This precision not only improves the quality of the models but also helps students identify potential flaws early in the design process.

5. Exposure to Advanced Manufacturing Techniques

CNC technology exposes students to advanced manufacturing techniques, including subtractive manufacturing, multi-axis machining, and digital fabrication. By learning to operate CNC machines, students become familiar with processes such as milling, turning, and drilling, all of which are integral to modern manufacturing. Engineering colleges that provide access to CNC technology help their students stay abreast of cutting-edge developments in the field.

6. Hands-on Training with Akriti Precision Systems Machines

As a leading Indian CNC Machine Manufacturer, Akriti Precision Systems designs machines that are ideal for educational institutions. Their machines combine advanced features with ease of use, making them suitable for both beginners and experienced users. By sourcing approximately 75% of components from local manufacturers and importing the rest from countries like Germany and Japan, Akriti Precision Systems ensures that their machines are both reliable and affordable.

7. Integration of CAD/CAM Software

One of the most beneficial uses of CNC machines in engineering education is the integration with CAD/CAM software. Students can design components in CAD programs and then use CAM software to convert those designs into instructions for the CNC machine. This process gives students an in-depth understanding of how design translates into actual manufacturing, enhancing both their design and technical skills.

8. Reduced Material Waste

CNC machines are also known for their efficiency in material usage. Unlike traditional machining, where human error can lead to material wastage, CNC machines operate with high precision, minimizing waste. This feature is particularly beneficial in an educational setting, where materials and resources are often limited.

9. Learning Industry-Standard Equipment

By using machines from Akriti Precision Systems, students get the opportunity to work with equipment that meets industry standards. This not only helps them become proficient in operating CNC machines but also prepares them to transition smoothly into professional environments after graduation. Akriti’s commitment to quality makes them a trusted Indian CNC Machine Manufacturer, offering top-notch educational tools.

10. Automating Complex Processes

CNC machines allow engineering students to automate complex manufacturing processes. This is especially useful when working on intricate designs or large-scale projects that would be too labor-intensive to complete manually. Automation enhances productivity and ensures consistent results, giving students a deeper understanding of modern engineering practices.

11. Collaborative Learning Environment

Another significant use of CNC machines is their ability to foster collaboration among students. CNC projects often require teamwork, from design and programming to execution and analysis. By working together, students develop essential communication and problem-solving skills, which are invaluable in both academic and professional settings.

12. Safety in Manufacturing

CNC machines come with built-in safety features that protect students from accidents during the machining process. These features include automated shutdowns, protective enclosures, and error detection systems. By using CNC technology, engineering colleges can provide a safer learning environment while still allowing students to engage in hands-on manufacturing.

13. Exploring Different Materials

CNC machines can work with a wide variety of materials, including metals, plastics, and composites. This versatility allows engineering students to explore different material properties and understand how they affect the manufacturing process. Machines from Akriti Precision Systems are equipped to handle these diverse materials, making them a valuable asset in educational settings.

14. Precision Machining in Research Projects

In addition to their role in teaching, CNC machines are often used in research projects within engineering colleges. Whether it’s developing new manufacturing techniques or testing material durability, CNC machines provide the precision required for high-quality research. Akriti Precision Systems, a renowned Indian CNC Machine Manufacturer, supplies colleges with machines capable of handling complex research applications.

15. Supporting the ‘Make in India’ Initiative

The machines produced by Akriti Precision Systems align perfectly with the ‘Make in India’ initiative. With 75% of the components manufactured in India, these CNC machines support local industries while maintaining global standards. This combination of local manufacturing and international quality control helps elevate the overall standard of CNC technology in India’s educational institutions.

FAQs

1. What is the importance of CNC machines in engineering colleges? CNC machines are crucial in engineering education as they offer hands-on experience in manufacturing, design, and material science.

2. Why are Akriti Precision Systems’ machines suitable for colleges? Akriti’s machines are designed for ease of use and come with advanced features, making them ideal for both educational and research purposes.

3. What are the uses of CNC machines in education? They help students learn prototyping, precision machining, and advanced manufacturing processes, preparing them for industry jobs.

4. How do CNC machines support innovation in engineering colleges? CNC machines allow students to experiment with complex designs and create custom prototypes, fostering innovation and creativity.

5. What makes Akriti Precision Systems a leading Indian CNC Machine Manufacturer? Akriti sources 75% of their machine components locally and ensures global quality by collaborating with international suppliers, offering high-quality CNC solutions.

6. Can CNC machines help reduce material waste in engineering projects? Yes, their precision minimizes material wastage, making them efficient and eco-friendly tools in educational environments.

Conclusion

The uses of CNC machines in engineering colleges are vast, from enhancing practical learning to preparing students for industry. With machines from Akriti Precision Systems, an established Indian CNC Machine Manufacturer, colleges can provide students with the best educational tools to master modern manufacturing technologies. These machines are a testament to the growing capabilities of India’s CNC industry, offering a blend of local expertise and international quality.