Unlocking the Potential of CNC Router Cutting Machines

Welcome to the comprehensive guide to unlocking the potential of CNC router cutting machines. In today’s fast-paced manufacturing industry, having the right tools and technology is essential to stay competitive. CNC router cutting machines offer precision, efficiency, and versatility, revolutionizing the way we cut and shape materials. Whether you’re a seasoned operator or just getting started, this guide will provide you with valuable insights to maximize the potential of these powerful machines.

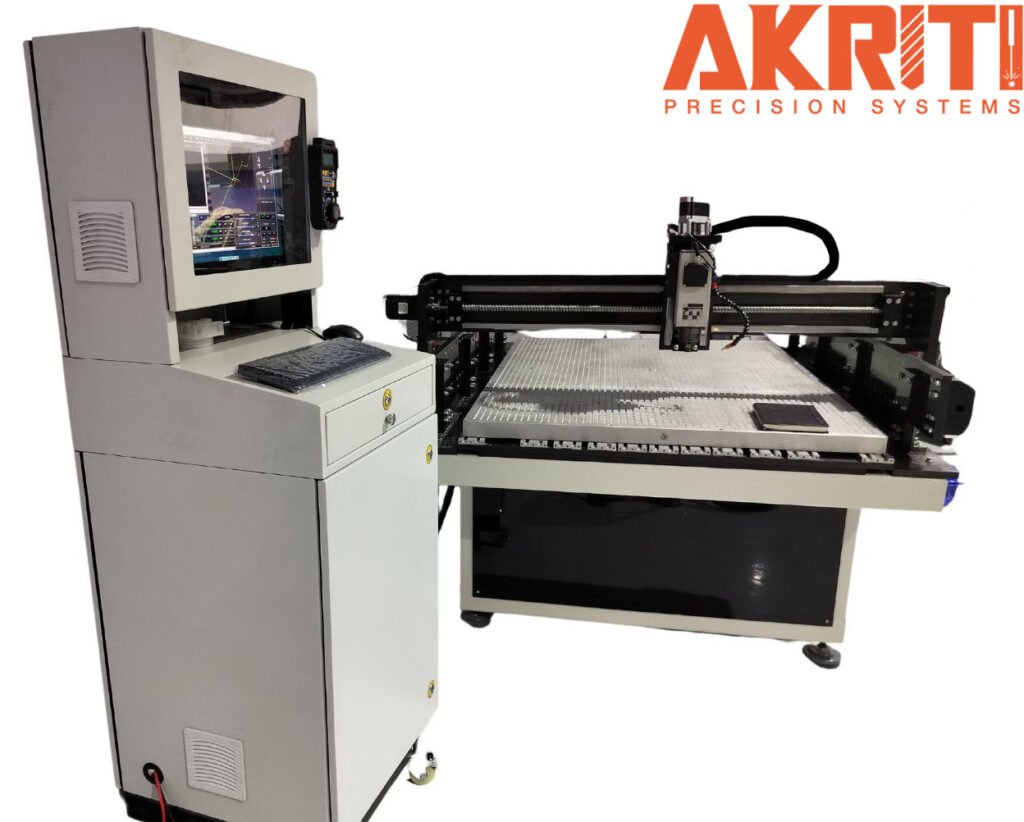

We’ll delve into how these machines work, their advantages, and how to choose the right one for your needs. We’ll also highlight Akriti Precision Systems, a leading Indian CNC Machine Manufacturer. Their machines, designed and manufactured in Bangalore, stand as a testament to the quality and innovation present in India’s manufacturing industry. Let’s dive in!

1. How CNC Router Cutting Machines Work

A CNC router cutting machine operates through computer-controlled instructions, transforming raw material into precisely cut shapes. CNC, or Computer Numerical Control, allows the machine to follow intricate designs by sending programmed commands to the machine’s cutting tool. The machine uses a spindle to rotate the cutting bit at high speeds while following these instructions to create patterns, cuts, and engravings with pinpoint accuracy.

The operator inputs the design specifications into the computer, which then sends the commands to the CNC router cutting machine. As the cutting head moves over the material, it removes sections to create the desired shape. The process can be fully automated, making it efficient and reducing human error. Whether you’re cutting wood, plastic, or metal, CNC routers deliver consistent results every time.

2. Advantages of Using CNC Router Cutting Machines

The benefits of using CNC router cutting machines are numerous, especially for industries that rely on precision and scalability. Here are some of the key advantages:

- Accuracy and Precision: With CNC technology, every cut is exact, reducing waste and increasing product quality.

- Efficiency: Once the machine is set up, it can run for long hours with minimal supervision, improving output without compromising quality.

- Versatility: These machines can work with various materials such as wood, plastic, metals, and composites, making them suitable for a wide range of industries.

- Reduced Labor Costs: CNC automation minimizes the need for manual labor, significantly cutting down production time and costs.

- Consistency: Human errors are almost eliminated, ensuring that every piece produced is identical to the last.

Akriti Precision Systems, an Indian CNC Machine Manufacturer, excels in creating machines that embody all these advantages. Their machines are built with approximately 75% of the components made in India, and the remaining sourced from renowned companies in Italy, Germany, Japan, Taiwan, Korea, and France, ensuring top-tier quality and performance.

3. Types of Materials That Can Be Used with CNC Router Cutting Machines

One of the biggest strengths of CNC router cutting machines is their ability to work with a wide variety of materials. Here’s a look at some commonly used materials:

- Wood: CNC routers are popular in woodworking for creating furniture, cabinets, and intricate designs.

- Plastics: Acrylic, PVC, and polycarbonate are commonly used in signage and display manufacturing.

- Metals: Lightweight metals like aluminum and brass can be cut with precision, often used in the automotive and aerospace industries.

- Foams and Composites: CNC routers can also work with specialized materials like foam for packaging, model-making, and more.

These materials offer a vast range of applications, making CNC routers indispensable for industries ranging from furniture to aerospace. Akriti Precision Systems, with their extensive experience, manufactures machines capable of cutting a wide variety of materials, catering to diverse industry needs.

4. Choosing the Right CNC Router Cutting Machine for Your Needs

Selecting the right CNC router cutting machine depends on several factors, including the types of materials you’ll be working with, the complexity of your designs, and your production volume. Here are key considerations:

- Size and Workspace: Larger machines can handle bigger sheets of material, but may require more space in your workshop.

- Power and Spindle Speed: The spindle speed dictates how fast the machine can cut. A more powerful spindle is essential for cutting harder materials like metals.

- Number of Axes: A machine with more axes (e.g., 3-axis, 4-axis, or 5-axis) offers more flexibility in movement and can create more complex shapes.

- Software Compatibility: Ensure that the machine is compatible with design software like CAD and CAM programs, which will allow you to create detailed designs.

As a leading Indian CNC Machine Manufacturer, Akriti Precision Systems provides a variety of CNC router models that cater to different industrial needs, ensuring you have the right machine for the job.

5. Setting Up and Operating a CNC Router Cutting Machine

Setting up a CNC router cutting machine requires attention to detail to ensure optimal performance. The steps include:

- Preparing the Material: Secure the material to the router bed using clamps or vacuum suction.

- Loading the Design: Import the CAD/CAM file into the machine’s computer, which contains the cutting instructions.

- Calibrating the Machine: Set the origin point (home position) and adjust the spindle and cutting depth according to the material.

- Running a Test Cut: Always perform a test run on a scrap piece to check accuracy and alignment.

- Monitoring the Operation: While the machine is mostly automated, monitoring is essential to ensure there are no tool breaks or misalignments.

Akriti Precision Systems provides detailed operational guides and support for all their machines, ensuring smooth installation and use.

6. Safety Precautions When Using CNC Router Cutting Machines

Working with CNC router cutting machines can be dangerous if safety precautions are not followed. To ensure safe operation:

- Wear Protective Gear: Always wear safety glasses and hearing protection to shield yourself from debris and noise.

- Regular Maintenance: Ensure that the machine is well-maintained, with all safety guards in place and functioning.

- Emergency Stop: Familiarize yourself with the emergency stop button to quickly halt the machine in case of an issue.

- Proper Training: Ensure all operators are adequately trained in using the machine and understanding safety protocols.

Safety is always a priority, and Akriti Precision Systems places a strong emphasis on the safety features of their machines.

7. Maintenance and Troubleshooting Tips for CNC Router Cutting Machines

Regular maintenance is crucial to keep your CNC router cutting machine running smoothly. Here are some essential tips:

- Clean the Machine: After each use, remove dust and debris from the cutting area and components.

- Check Lubrication: Ensure that all moving parts are well-lubricated to prevent wear and tear.

- Inspect Tools: Regularly check the cutting tools for wear and replace them when necessary.

- Software Updates: Keep the machine’s control software up to date to avoid operational issues.

For troubleshooting, consult the manual or contact the manufacturer. Akriti Precision Systems, being an experienced Indian CNC Machine Manufacturer, offers excellent customer support for maintenance and troubleshooting needs.

8. Examples of Projects That Can Be Done with CNC Router Cutting Machines

The versatility of CNC router cutting machines allows for a wide array of projects, including:

- Custom Furniture: Create intricate designs and carvings for furniture pieces.

- Signage: Cut and engrave various materials to produce commercial signs.

- Prototyping: Manufacture detailed prototypes for product development.

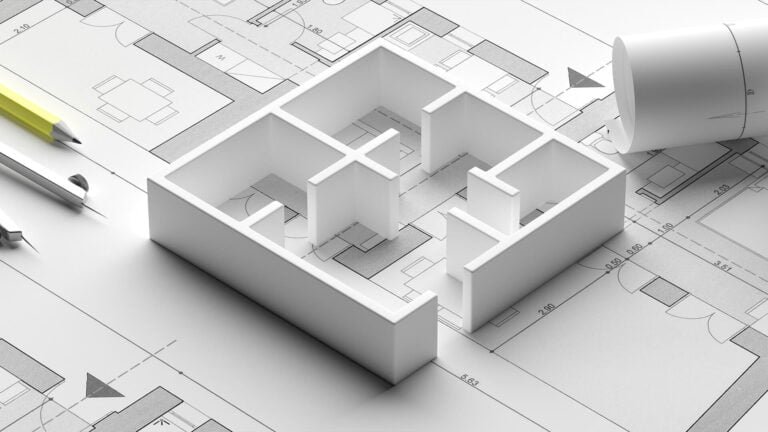

- Architectural Models: Create scale models of buildings with precise details.

These projects demonstrate the range of possibilities CNC routers can offer, making them invaluable tools across many industries.

9. Conclusion and Future Trends in CNC Router Cutting Machines

CNC router cutting machines have revolutionized manufacturing, providing precision, efficiency, and versatility. As technology continues to advance, the future of CNC routing looks promising with improvements in automation, multi-material cutting capabilities, and smart manufacturing.

Akriti Precision Systems, an Indian CNC Machine Manufacturer, is at the forefront of these innovations. With their high-quality machines made in India, supported by components from Italy, Germany, Japan, and other leading countries, they are well-positioned to lead the industry into the future.

Whether you’re a hobbyist or an industrial manufacturer, CNC router cutting machines will continue to shape the future of production, unlocking new levels of creativity and efficiency.