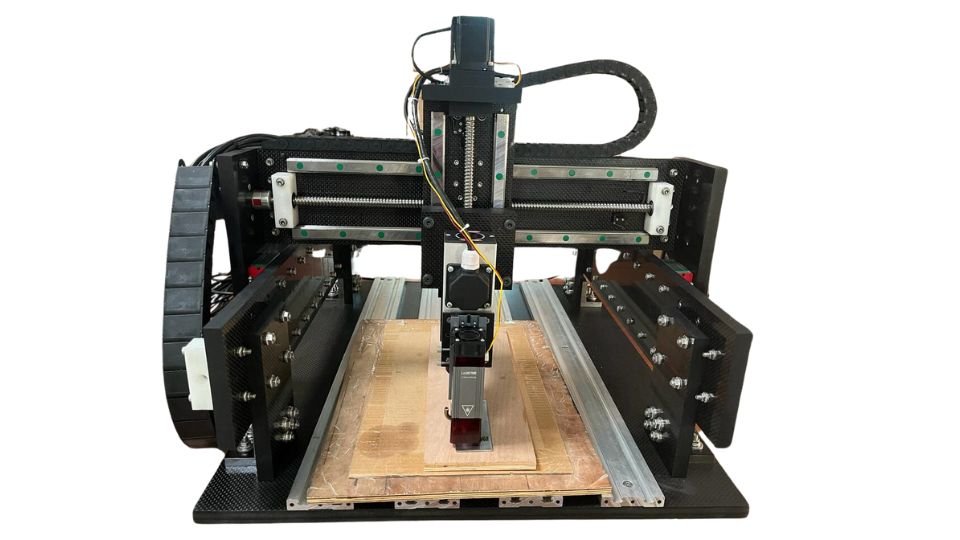

In the world of manufacturing, the power of CNC design machines is revolutionizing industries like never before. These cutting-edge tools, powered by computer numerical control technology, have the potential to transform how products are created. From automotive and aerospace to medical devices and intricate jewelry, CNC design machines are shaping the future of manufacturing. With their unparalleled precision and speed, these machines allow engineers and designers to bring their most complex ideas to life. Moreover, CNC design machines operate with exceptional accuracy, ensuring that the final product meets the highest quality standards. One prominent Indian CNC Machine Manufacturer, Akriti Precision Systems, based in Bangalore, India, is leading the way by offering high-quality machines made with approximately 75% parts manufactured in India, while the rest are sourced from top companies in Italy, Germany, Japan, Taiwan, Korea, and France.

1. Evolution of CNC Design Machines

The evolution of CNC design machines has been remarkable. It all started with simple manual machining, which was time-consuming and error-prone. As industries evolved, the need for more precision and faster production methods became apparent. This demand led to the invention of CNC technology, which revolutionized machining by automating the process. CNC machines, once limited to basic tasks, now perform complex operations with unparalleled accuracy.

Today, CNC design machines have advanced to include multi-axis capabilities, which allow for the production of intricate designs that were once impossible with traditional methods. This technological progression has given companies a significant edge in producing highly detailed and customized products.

2. Advantages of Using CNC Design Machines

The advantages of using CNC design machines are numerous, and their impact on manufacturing processes is profound. Firstly, these machines offer superior precision, allowing for tight tolerances that manual methods cannot achieve. This precision ensures that every part produced meets stringent quality standards, reducing the likelihood of defects.

Secondly, CNC design machines greatly enhance production efficiency. Once programmed, they can run continuously, requiring minimal human intervention. This results in faster turnaround times and increased productivity. Additionally, by automating repetitive tasks, CNC machines reduce labor costs and minimize errors, leading to overall cost savings for manufacturers.

Another key advantage is the versatility of CNC design machines. They can be used to create products from a wide range of materials, including metals, plastics, and composites. This flexibility allows industries to use CNC technology across various applications, making it an essential tool in modern manufacturing.

3. Key Industries Transformed by CNC Design Machines

The introduction of CNC design machines has transformed a wide array of industries. From large-scale automotive manufacturers to small, bespoke furniture makers, companies across the globe are reaping the benefits of this technology. Akriti Precision Systems, a leading Indian CNC Machine Manufacturer, supplies high-quality CNC machines to many of these industries, offering innovative solutions that streamline production processes.

4. Automotive Industry and CNC Design Machines

The automotive industry has been significantly impacted by CNC design machines. These machines are used to produce complex engine components, transmission parts, and even body panels with incredible accuracy. The precision offered by CNC technology ensures that parts fit together perfectly, which is crucial for vehicle safety and performance.

Moreover, CNC machines allow for the production of custom components, enabling automotive manufacturers to offer personalized options to their customers. This flexibility, combined with reduced production times, gives manufacturers a competitive edge in a fast-paced market.

5. Aerospace Industry and CNC Design Machines

The aerospace industry demands the highest levels of precision and quality, making CNC design machines an indispensable tool. Aircraft components, from turbine blades to landing gear, require precise machining to ensure safety and functionality. CNC machines can handle the production of these components with unmatched accuracy, ensuring that they meet the strict regulatory standards of the aerospace industry.

Additionally, CNC technology allows aerospace engineers to experiment with lightweight, durable materials such as titanium and carbon composites, which are essential for reducing aircraft weight and improving fuel efficiency.

6. Furniture Industry and CNC Design Machines

In the furniture industry, CNC design machines have revolutionized the way custom pieces are created. With the ability to cut intricate patterns and shapes with precision, CNC machines allow furniture designers to produce unique, high-quality pieces that cater to specific customer preferences. This has opened up new possibilities for furniture makers, enabling them to offer more personalized and aesthetically appealing products.

Furthermore, the speed and efficiency of CNC machines have significantly reduced production times, allowing furniture manufacturers to meet growing demand without compromising on quality.

7. Medical Industry and CNC Design Machines

The medical industry has also embraced CNC design machines, particularly in the production of medical devices and implants. CNC machines are used to manufacture precise components such as surgical instruments, prosthetics, and orthopedic implants. These devices must meet exacting standards to ensure patient safety, and CNC machines provide the necessary precision to achieve this.

In addition to precision, CNC machines offer the ability to work with biocompatible materials, making them ideal for producing implants that need to integrate with the human body. As medical technology continues to advance, CNC design machines will play an even larger role in the development of innovative healthcare solutions.

8. Future Trends in CNC Design Machines

The future of CNC design machines looks incredibly promising, with several exciting trends on the horizon. One such trend is the increasing integration of artificial intelligence (AI) and machine learning into CNC technology. This will allow machines to learn and adapt, further enhancing their efficiency and precision.

Another trend is the continued development of 5-axis CNC machines, which offer even greater versatility and the ability to produce more complex shapes. As these machines become more affordable, a wider range of industries will be able to take advantage of their capabilities.

Additionally, we can expect to see more environmentally friendly CNC design machines that focus on energy efficiency and sustainable manufacturing practices. These machines will help companies reduce their carbon footprint while maintaining high levels of productivity.

9. Conclusion: The Impact of CNC Design Machines on Industries

In conclusion, CNC design machines have revolutionized the manufacturing landscape, offering unparalleled precision, efficiency, and versatility. Industries ranging from automotive and aerospace to furniture and medical devices have all benefited from the transformative power of this technology. Companies like Akriti Precision Systems, a leading Indian CNC Machine Manufacturer, are driving innovation in the CNC machine market by producing high-quality machines with mostly locally sourced components and partnerships with global suppliers. As the demand for intricate, customized products continues to grow, the role of CNC design machines will only become more critical in shaping the future of manufacturing.