Have you ever admired the intricate gears within a complex machine, each one working together in a mesmerizing dance of power and motion? The secret behind these marvels often lies in CNC (Computer Numerical Control) machining. CNC technology transforms raw materials into precisely designed parts, and it’s not just reserved for large-scale production anymore!

Let’s dive headfirst into the exciting world of parts manufacturing with CNC machines and explore how it can be used to create gear-based designs, empowering hobbyists and small businesses alike.

Why Choose CNC for Gear Manufacturing? Precision Takes the Wheel

Gears are the backbone of many machines, transmitting power and motion with smooth efficiency. Their success hinges on two crucial elements: perfect tooth profiles and precise tolerances. This is where CNC machining truly shines:

- Uncompromising Accuracy: Unlike traditional methods, CNC machines translate digital designs into reality with astonishing precision. Every gear tooth is meticulously carved, ensuring smooth meshing and optimal performance for your project.

- Repeatability Redefined: Need multiples of the same gear, all identical? No sweat! CNC machining guarantees consistent quality, part after part, so all your gears work in perfect harmony.

- Material Versatility: CNC machines are material chameleons. Whether you require heavy-duty metal gears for industrial machinery or lightweight plastic gears for prototypes, CNC machining can handle a wide range of materials, offering the perfect solution for your specific needs.

Beyond Gears: Unleashing the Full Potential of CNC

The true beauty of CNC manufacturing lies in its versatility. While it excels at gear creation, it unlocks a vast array of possibilities for parts manufacturing:

- Custom Components: Bring your innovative ideas to life! CNC machines can create unique, non-standard parts that traditional manufacturing might struggle with, allowing you to push the boundaries of design.

- Prototyping Powerhouse: Don’t wait to test your gear designs before mass production. CNC machining allows for rapid prototyping, enabling you to refine and iterate quickly, ensuring your final product is perfect.

- Small Batch Production: Need a limited run of specialized gears for a niche project or to kickstart your entrepreneurial venture? CNC manufacturing caters to small batch production runs, making it ideal for getting your ideas off the ground.

Akriti: Your Precision Machining Partner

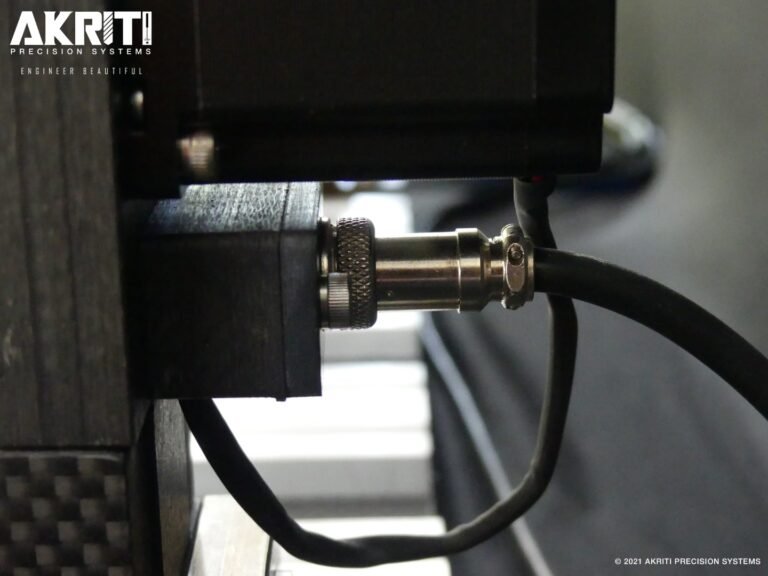

At Akriti Precision Systems, we understand the critical role of precision and reliability in your projects. Our top-of-the-line CNC machines are built with ZERO Chinese parts and guarantee accuracy up to 3.5 microns. We offer a wide range of CNC machines to suit projects of all sizes.

Don’t wait! Turn your gear-based ideas into reality with the power of CNC machining. Contact Akriti Precision Systems today and discover how we can help you [link to Contact Us page]. Visit https://akriti.tech to learn more!

Akriti: Where precision meets innovation, one gear at a time!

A simple set of gears being made with wood. Gears have various applications, and making them quickly and efficiently is key.

![]()

Making the model from the image above.

More Details are available here – https://www.instructables.com/Wooden-Gear-Trains/

The designer here has used a laser but this can also be achieved with a CNC. The design file is also included on the website.